Important document information

Levelflex FMP53 HART

4

Hauser

1

Important document information

1.1

Symbols

1.1.1

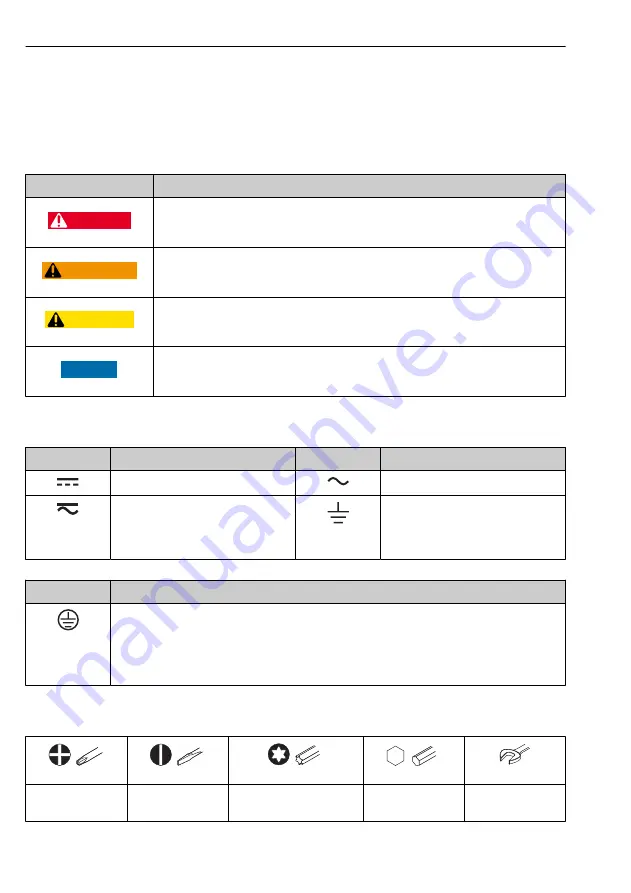

Safety symbols

Symbol

Meaning

DANGER

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTICE

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.1.2

Electrical symbols

Symbol

Meaning

Symbol

Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

Symbol

Meaning

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

1.1.3

Tool symbols

A0011219

A0011220

A0013442

A0011221

A0011222

Cross-head

screwdriver

Flat blade

screwdriver

Torx screwdriver

Allen key

Hexagon wrench

Summary of Contents for HART Levelflex FMP53

Page 43: ......