13

www.uniquip.ca

machine or losing parts and creating debris that could jam the machine and cause it to

malfunction.

v.Are the coring tines engaged in the traveling position (i.e: raised from the working surface)?

Ensure that the coring reel is securely raised away from the working surface until arrival at

jobsite. Moving the aerator with the coring tines in the lowered working position can damage

the unit and jobsite.

b.Inspect the handle for the following:

i.Is the handle properly and securely attached to the machine?

ii.Is the handle set in the correct operating position and secured by locking the cam lock?

c.Consult the “Inspection Schedule” section of this manual and verify that:

i.The ball bearings, casters and chain are lubricated and in good condition.

ii.The coring tine reel and coring tines are clean and not in need or replacement. Consult the

“Maintenance Procedures” section of this manual for guidelines and instructions on when and

how to change the coring tines.

iii. The drive belt and chain are in good condition and set to the appropriate tension. Consult the

“Maintenance Procedures” section of this manual for guidelines and instructions on taking care

of the belt and chain.

iv. The torque on the tine reel nut is set to 100 ft.lbs/135.58 Nm. Reset the torque with a torque

wrench to the appropriate level.

2.Before operating the aerator perform the following environmental checks:

a.Is the ground where the aerator will be operating level and solid? If it is a slope of

more than 35% grade, please refer to “Aerating on Inclined Surfaces” under the

“Operation Procedures” section of this manual.

b.Has the lawn been cleared of debris such as string, wire, rocks, metal and other

materials? Such items could cause malfunction or damage to the aerator that could

also be potentially hazardous to the machine and operator.

c.Are all obstructions such as sprinkler lines, electrical boxes, fences etc. clearly marked?

Pre-Operation Procedures cont’d ...

!

THE NUT MUST BE MAINTAINED AT THE APPROPRIATE TORQUE OR

THE MACHINE CAN MALFUNCTION, THEREBY CAUSING SEVERE

BODILY DAMAGE AND/OR PROPERTY AND JOBSITE DAMAGE.

!

If any of the above checks fail, please take necessary steps to

maintain or repair the unit before operating it in any environ-

ment.

Summary of Contents for ENAR24HC

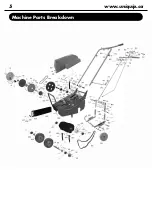

Page 10: ...5 www uniquip ca Machine Parts Breakdown...

Page 27: ...22 www uniquip ca Notes...