12

Field Boss™ Xstream

English

5)

Once the boom is secure, tighten the

hardware on the boom brackets to make

sure they are also secure.

6)

Take the feed hoses from boom and

connect to male brass hose fittings on

spray unit. Hook hoses up to the appro-

priate section control; 12’, 20’ and 30’

booms have 3 hose hookups and boom-

less nozzle has 2 hose hookups.

Mounting Your Boom

7)

If you got the 30’ boom extensions,

once the 20’ boom is mounted, bolt on

the extensions to the boom ends.

8)

Then, hook up the hoses using the

brass threaded connectors.

GETTING STARTED

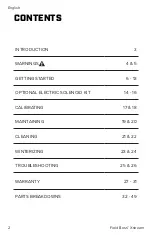

Summary of Contents for FIELD BOSS XSTREAM SFB060FG290EX

Page 32: ...32 Field Boss Xstream English SFB100FG290EX...

Page 34: ...34 Field Boss Xstream English DETAIL VIEW A 44 28 26 31 4 30 41 3 8 29 2 27 30 25 12 DETAIL A...

Page 39: ...39 Version 1 9 English SFB100FG290EX ES...

Page 41: ...41 Version 1 9 English VIEW A 4 3 9 7 29 8 26 37 10 36 38 39 6 27 64 30 28 23 22 DETAIL VIEW A...