14

Operating Instructions and Owner’s Manual

Master Forge Wood Pellet Fire Stove

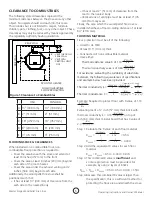

CAUTION: ENSURE THAT THE FIREPOT AND

THE PAN UNDERNEATH ARE CLEAN AND IN

THE PROPER OPERATING POSITION BEFORE

USING THE STOVE.

WARNING: NEVER USE GASOLINE,

GASOLINE-TYPE LANTERN FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID, OR SIMILAR

LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE

IN THIS HEATER. KEEP ALL SUCH LIQUIDS

WELL AWAY FROM THE HEATER WHILE IT IS

IN USE.

PAINT CURING

To allow the paint to bond durably to the stove, start

by running the stove on P1 High Power for at least 30

minutes. Provide cross ventilation to eliminate odors or

smoke cause by this curing process.

OPERATING PROCEDURE: TURN ON STOVE

NOTE:

If the display screen indicates that the

stove is “Switching Off” the stove can not

be interrupted. The Display Message will

highlight to indicate that the state will not be

changed. Only once the “Switching Off” cycle

has finished and the exchanger has cooled

can the stove be turned back on again.

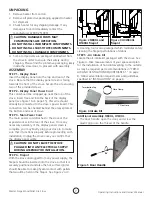

1. Make sure that seals on the ash drawer and door

are in good condition. If the stove has never been

run before, add a handful of pellets directly to the

firepot. Close the ash drawer and doors securely,

and check that all side panels are all properly

installed.

NOTE:

DO NOT USE GRATES, IRONS, OR ANY

OTHER METHODS OF SUPPORTING WOOD

PELLET FUEL. ONLY THE FIREPOT SPECIFIC

TO YOUR MODEL OF STOVE MAY BE USED.

2. Open the hopper. Ensure that there are a

sufficient number of pellets to satisfy your heating

requirements. Close the hopper.

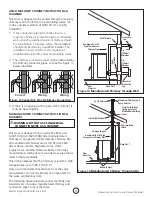

3. Depress the power button

for 3 seconds. The

stove will begin to automatically progress through

the following stages:

•

Cleaning Cycle: The firepot draws dust, ash, &

remnants out.

•

Feeding Cycle: Pellets will be transported from the

Pellet Hopper into the fire pot by the auger. This

can take 5 to 15 minutes depending on the model

of stove.

•

Lighting Cycle: The electrically powered hot surface

igniter will power on for 8 minutes and begin

combustion of the pellets in the firepot. The heater

will remain in the Lighting Cycle until the exhaust

smoke reaches a designated temperature.

•

Stabilization Cycle: The heater adjusts to fine tune

the stove output to the desired temperature. This

can take a few minutes

4. The stove has been successfully turned on.

OPERATING PROCEDURE: TURN OFF STOVE

NOTE:

THE STOVE MAY BE TURNED OFF,

REGARDLESS OF WHAT CYCLE THE DISPLAY

SCREEN INDICATES THAT THE STOVE IS IN,

BY DEPRESSING AND HOLDING THE POWER

BUTTON FOR TWO SECONDS. ONCE THE

DISPLAY SCREEN INDICATES THAT THE

STOVE IS IN THE STABILIZATION CYCLE

PRESS THE POWER BUTTON AGAIN. THE

STOVE WILL ENTER THE COOLING CYCLE,

STATED ON THE DISPLAY SCREEN.

CAUTION: AFTER THE COOLING CYCLE THE

STOVE AUTOMATICALLY BEGINS

THE PROCESS OF CYCLING ON.

1. Depress the power button for 3 seconds. The stove

will begin to automatically progress through the

following stages:

•

Switching Off: Any remaining fuel in the firepot

will continue to burn and produce heat and

flame. After 5 to 8 minutes the firepot ought to

be devoid of fuel. The heat exchanger may then

begin to cool off.

•

Goodbye: The final message from the display

screen to designate that the stove has cooled.

2. The stove has been successfully turned off.

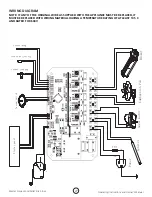

OPERATION WITH AN ELECTRICAL GENERATOR

This stove is designed to have the option of being

powered by an electrical generator, though not

all electrical generator’s may be compatible with

this stove. Consult the information regarding your

generator’s electrical regulator and make sure that

it meets the electrical requirements of this stove, as

stated on page 3.

MINIMIZING CREOSOTE FORMATION

See “MAINTENANCE” on page 19 for an explanation

of Creosote formation and removal. To slow the build

up of creosote within your chimney burn only the

recommended fuel, see page 13.