ML0071-601-06 Super Seal™ Operations Manual Rev. A

ENERCON INDUSTRIES

17

TROUBLESHOOTING

” in

SECTION 6 –

TROUBLESHOOTING

.

Once the system is running it is recommended that

you attempt to determine the sealing window of the

products that will be sealed by this power supply.

This test will require several containers, caps, and

liners and should be performed at the line speed

each product will be run at during actual production.

NOTE:

The initial output level chosen for this test can be a

level determined by the testing results of your

product samples by Enercon, or an output level of

your own choosing. If no samples were sent for

testing, it is recommended that the initial output level

be 50% or lower. For the following examples, we will

be using 50% as the initial output level.

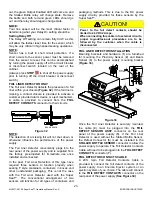

With the circuit breaker or disconnect switch ON,

press the

UP

/

DOWN

arrows until the

desired output level setpoint is reached. Press the

START

pushbutton and ensure the unit starts

and is running at the output level you selected.

Run a single container under the sealing head at

your production line speed. Once through the sealer,

wait at least 30 seconds for the liner to cool and then

remove the cap and inspect the liner condition.

NOTE:

Do

not

perform this test on a container that has been

previously run, as this can give inaccurate test

results. A new container, liner, and cap should be

used each time the test requires a container to be

run.

No Seal

If no seal was achieved, raise the output in 5%

increments and continue running a single container

until the liner begins to adhere. Continue the test,

raising the output by 1% or 2%, until the liner seals

around the entire lip of the container. This is the

lower limit of the sealing window. Continue the test,

raising the output by 1%, until the liner shows signs

of overheating then lower the output by 1% and this

is the upper limit of the sealing window. Choose the

output level, within this window, that gives the

desired strength and peelability as your production

output level.

Burned Liner

If the initial test results in a burned liner, lower the

output in 5% increments and continue running a

single container until the burning subsides. Continue

the test, lowering the output by 1% or 2%, until the

liner shows

no

signs of overheating. This is the

upper limit of the sealing window. Continue the test,

lowering the output by 1%, until the liner no longer

seals the entire lip of the container. Raise the output

by 1% and this is the lower limit of the sealing

window. Choose the output level, within this window,

that gives the desired strength and peelability as

your production output level.

Good Seal

If a good seal was achieved, note the output level,

then lower the output 1% and continue running a

single container until the liner no longer seals the

entire lip of the container. Raise the output by 1%

and this is the lower limit of the sealing window.

Reset the output to the level noted after the initial

test. Continue the test raising the output by 1% until

the liner shows signs of overheating. Lower the

output by 1% and this is the upper limit of the sealing

window. Choose the output level, within this window,

that gives the desired strength and peelability as

your production output level.

Production Test

When the sealing window and production output %

have been determined, a production test should be

run. Set up a group of containers that is at least

twice the length of the sealing head. The grouping

should be back to back to simulate a worst case

scenario. Press the

START

pushbutton and

verify the unit is running at your production output

level determined in the previous steps. Run the

containers at your production line speed and then

verify that all containers sealed properly.

If not all of the containers sealed, double check the

results of the sealing window setup and refer to

“

APPLICATION TROUBLESHOOTING

” in

SECTION 6 – TROUBLESHOOTING

of this manual.

If all of the containers sealed properly, then the

system is ready to be put into production.

ADJUSTING THE LOSS OF SEAL INDICATOR

ALARM SETPOINT

The Loss of Sealing Indicator Alarm (LSI) is

programmable to allow setting the power supply’s

lower output limit, or threshold, for the alarm circuit

operation. If, for any reason, the output displayed on

the output meter falls below this programmed alarm

setpoint the alarm relay contacts will change state.

Refer to

LOSS OF SEALING INDICATOR ALARM

(LSI

) on

Page

14

for more information.

The default alarm setpoint is 60%, and is set during

the testing phase of the power supply. You will be

able to adjust the alarm setpoint to any level through

the full output range of your power supply.