ML0071-601-06 Super Seal™ Operations Manual Rev. A

ENERCON INDUSTRIES

25

b)

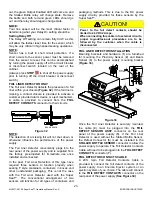

Remove the sensitivity adjustment pot cover

screw

(Figure 37)

.

c) With a container (and foil-lined cap) under the

proximity sensor, verify that the LED is ON. If LED

is OFF go to Step (

e

).

d) Turn the sensitivity adjustment CW (clockwise)

until the LED just turns OFF. In some cases, the

LED will not turn OFF

.

If not

,

proceed to

Step (

f

).

e) Turn the sensitivity CCW (counter clockwise) until

the LED just turns ON.

LED

Cover

Screw

Sensitivity

Adjust

Figure 37

f) Remove the container and the LED should turn

off.

g)

Turn the potentiometer CCW (counting the

number of turns) until the LED just turns ON.

h) Back off half the number of turns counted in Step

(

g

).

i) The LED should now be OFF. Sensitivity should

now be set at optimum.

AUTO MODE

The AUTO Mode Option is offered with the Super

Seal™ power supply as a way to automatically

control the power supply output from an external

source. This option allows the raising and lowering of

the Output level using an isolated 0–10 VDC signal

that you provide. The unit also provides a 0-10 VDC

output signal for monitoring of the output level. A

three wire cable is provided to connect to the

AUTO

CONTROL

connector on the rear panel of the power

supply

(Figure 38)

.

The cable wiring is

white

/ 0-10

VDC input signal,

red

/ 0-10 VDC output signal,

black

/ common and a

shield

.

To enter

AUTO MODE

the

AUTO/MANUAL

pushbutton on the front of the power supply must be

pressed. The

AUTO

LED should be lit. It is required

to press the

START

pushbutton on the

membrane panel to start the unit.

REMOTE START /

INTERLOCKS

AUTO

CONTROL

STALLED

BOTTLE SENSOR

FOIL DETECT

SENSOR ASSY

STAC

LIGHT

FOIL DETECT

CONTACTS

LSI

CONTACTS

BLACK (COM)

SHIELD

WHITE (0-10VDC IN)

RED (0-10VDC OUT)

Figure 38

Raising and lowering the 0-10 VDC being fed to the

unit will raise and lower the output of the power

supply. Maintain the minimum output level as

discussed under

ADJUSTING THE LOSS OF SEAL

INDICATOR ALARM SETPOINT

on

Pages 17

-

18

,

for the model power supply being used.

NOTE:

Slightly less than 10 VDC may achieve 100%

Output, limit voltage to achieve 100% maximum on

Output Meter.

DANGER!

When the AUTO Mode Cable is connected to

external circuits, these circuits must be de-

energized and locked out when the cable is

disconnected at the power supply.

JECTOR SYSTEM

The Enercon Eject System was designed to provide

a simple ejection system to remove rejected

containers off your conveyer. The Eject System can

be used with the Motion/Foil Detection Group, Foil

Liner Detector only, or other container inspection

systems that provide a dry contact closure when a

reject is detected. The system accepts the contact

closure and once timed out, the Eject System is

activated, causing the plunger to eject the container

off the conveyor. Refer to Ejector Manual

(ML0068-

001-XX)

and Drawings supplied with the Eject

System for more detailed information.

JECTOR INSTALLATION

Mounting brackets and hardware are (

1

) furnished

for mounting the Ejector (

2

) to your conveyor

(See

Figure 39)

. The Ejector is designed to work with the

Optional Enercon Foil Liner Detector and should be

mounted downstream of the detector in a location

that will allow the ejected containers to be collected.