ENERGETICA ENERGIETECHNIK GMBH

Adi-Dassler-Gasse 6 | A-9073 Klagenfurt-Viktring

Tel. +43 (0) 463 22500-0 | Fax. +43 (0)463 22500-22 | Email: office@energetica-pv.com

A

A

A

ATTENTION

TTENTION

TTENTION

TTENTION!!!!

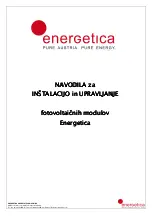

•

Only fasten and install the modules with the mounting

system that is provided or with a suitable corrosion-

resistant mounting system.

•

During the installation of the modules, make sure that there

is enough air circulation to cool the modules.

•

Only mount the module upright with the junction box up, or

mount it crosswise.

•

The modules must be fastened on four points, in each of

the quarter points of the long side in a stipulated clamping

area. Fastening on the short sides of the module is not

permitted. (See drawing)

Suitable Environmental Conditions:

Suitable Environmental Conditions:

Suitable Environmental Conditions:

Suitable Environmental Conditions:

The module is designed for use in moderate climatic conditions.

It must not be immersed nor be subjected to constant exposure

to water. In the event of environmental conditions involving

exposure to salt (500 m away from sea) and sulphur (sulphur

sources, volcanoes), there is a risk of corrosion which voids the

warranty. The module must not be subjected to chemical

pollution (e.g. emissions from plants). Ask for our mounting

system for optimum mounting results for Energetica PV modules.

Wiring:

Wiring:

Wiring:

Wiring:

All electrical work may only be performed by trained specialists

or alternatively an authorised electrician. Energetica photovoltaic

modules have a permanently installed junction box with

integrated bypass diodes and preinstalled connectors. That way,

the modules can be conveniently connected in series. The

connecting box and plug connectors may not be cleaned with

substances containing oil, grease, or alcohol. The placement of

multiple PV modules on a support system with common wiring is

referred to as a module string. Ask for our 6mm

2

solar cable for

wiring the module string to the inverter.

Modul

Modul

Modul

Module grounding:

e grounding:

e grounding:

e grounding:

The specific requirements (e.g. lightning protection) are to be

taken from the applicable regional and local regulations for the

grounding of photovoltaic systems and mounting frames.

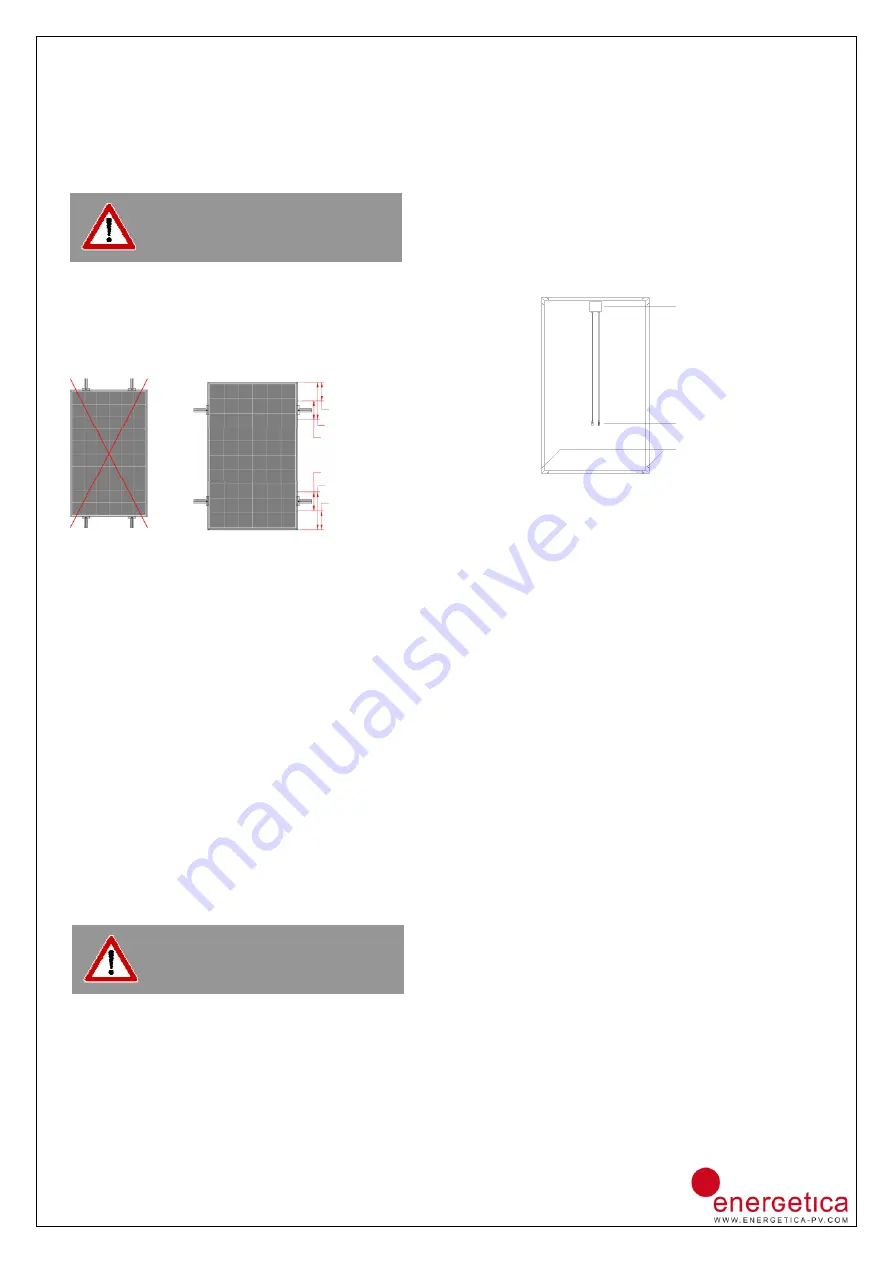

When grounding the module frames, only use the marked earth

connection points that are designated for that purpose (see Fig.

1). Furthermore, the grounding must not be broken or destroyed

during the maintenance of a module. The connection must be

made such that non-conductive coatings like paint, anodic

treated coatings, etc., are penetrated (e.g. by using toothed lock

washers or the like). In addition, any connecting elements that

are used must be made of rustproof materials. When

dimensioning the grounding elements and when connecting

them to a grounding system, both the local regulations as well as

generally recognised rules of engineering or alternatively

standards must be observed. Grounding may only be carried out

by qualified electricians.

Figure 1

Series and parallel connection of the modules:

Series and parallel connection of the modules:

Series and parallel connection of the modules:

Series and parallel connection of the modules:

With series connections, the module voltage adds up, and the

module current adds up with parallel connections. The applicable

regulations regarding electrical safety must be complied with.

The maximum system voltage given in the appendix, in the

datasheet, and on the type plate must not be exceeded, even at

very low temperatures. When connecting module strings together

in parallel, make sure that any return current caused by a fault

can never exceed the value of the maximum return current load

capacity of the modules, or alternatively that appropriately

dimensioned safety devices like line diodes or fuses are built in.

Shading:

Shading:

Shading:

Shading:

Energetica photovoltaic modules have bypass diodes that are

built into the junction box at the factory, which provide efficient

protection of the cells during shading. Shading of individual cells

or modules causes the shaded area to heat up because the

current of another cell string flows into the shaded area. By using

bypass diodes, the current from the shaded cell is diverted. This

reduces the heating of the cell and increases the performance of

the module under shady conditions. If a module string is

connected in parallel to a series connection, then switch one of

the power adapted blocking diodes in the direction of the current

in one connecting lead of each module string of the parallel

group. Alternatively, direct current line fuses can also be

installed instead of the additional diodes. They must be

configured in accordance with the short-circuit current given in

the datasheet. In the event of shading of the module string, the

first variation is preferred.

Attention!

Attention!

Attention!

Attention!

When installing the module, always make sure

that there is sufficient back ventilation to

ensure optimum heat dissipation.

Attention!

Attention!

Attention!

Attention!

The connection box must not be subjected to

high strain / pressure. If it is destroyed, there

is a danger of an electric shock.

1/8 module length

1/4 module length

clamping area

clamping area

1/4 module length

1/8 module length

Junction box

connector

grounding point