Transport and care

Transport and Storage

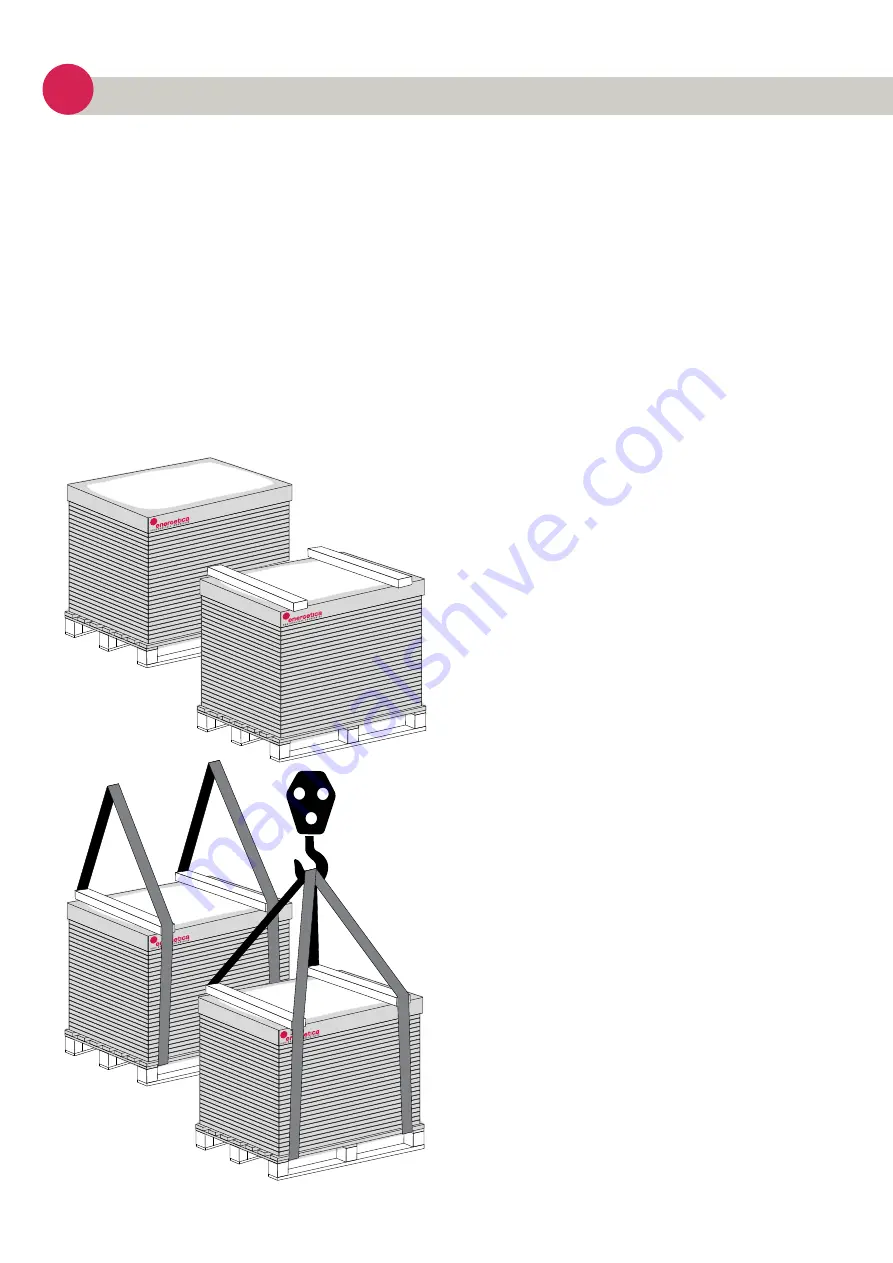

»

Never loosen the straps on the packaging during trans

port. If the straps are released, the module is unsecured

in the stack and can be damaged when accelerating,

braking or lifting.

»

For transport, stack the product only on the special pallet

provided by Energetica.

»

The maximum stacking height is two pallets. Stacking too

high can put too much pressure on the lower modules

and damage modules.

»

Never transport the module on one side of the frame or

on the cable. This can cause damage to the frame or

cables.

Cleaning

PV modules do not need to be cleaned to work effectively.

However, by removing dirt or deposits (leaves, snow) on the

front glass, their performance can be increased. Only clean

the modules when they have cooled down. Do not wear any

electrically conductive parts on your body or clothing.

In order not to damage the module surface, clean the

modules as follows:

»

Remove snow and ice carefully and without effort. For

example, use a soft broom for this;

»

Do not scrape off dirt or leaves, but rinse with lukewarm

water;

»

To do this, use an alcohol-based glass cleaner;

»

Do not use abrasive cleaning agents or tensides;

»

Carefully remove stubborn dirt with a cellulose cloth

(kitchen roll) or a damp, soft sponge. Do not use micro-

fiber or cotton cloths for this.

»

Stubborn soiling can be removed with isopropanol

within one hour of its occurrence (observe safety instruc

tions!).

»

Do not let any isopropanol run between the module and

the frame or into the module edges.

»

Water, ethanol and microfiber cloths can be used for

regular cleaning of the front glass.

»

Do not use calcareous groundwater to clean the glass.

»

The frame surface can be cleaned of foreign matter

residues with a damp, non-scratching sponge or cloth

and then dried in the air or with clean chamois leather.

Page 10

e