Mechanical installation

Selection of modules

For detailed electrical data, please refer to the current

product data sheet.

Available at www.energetica-pv.com.

Only interconnect modules of the same type and the same

performance class to prevent damage to the modules.

Safety factors

During normal operation it is possible that modules

deliver a higher current and / or higher voltage than under

standardized test conditions:

»

When determining the current ratings (ISC) of conductors

and

»

When dimensioning controls that are connected to the

outputs of the solar modules

»

When determining the rated voltage values (VOC) of

components.

The applicable national regulations for the installation of

electrical systems must be followed.

Series connection

Series connection of the modules is only permitted up to the

maximum system voltage specified in the applicable data

sheet.

»

The design must take into account all operating

cases, temperatures and relevant technical regulations

and standards.

This ensures that the maximum system voltage, including

the required safety margins, is not exceeded.

»

When designing the string length: Take into account the

voltage limitation of the inverter when determining the

number of modules.

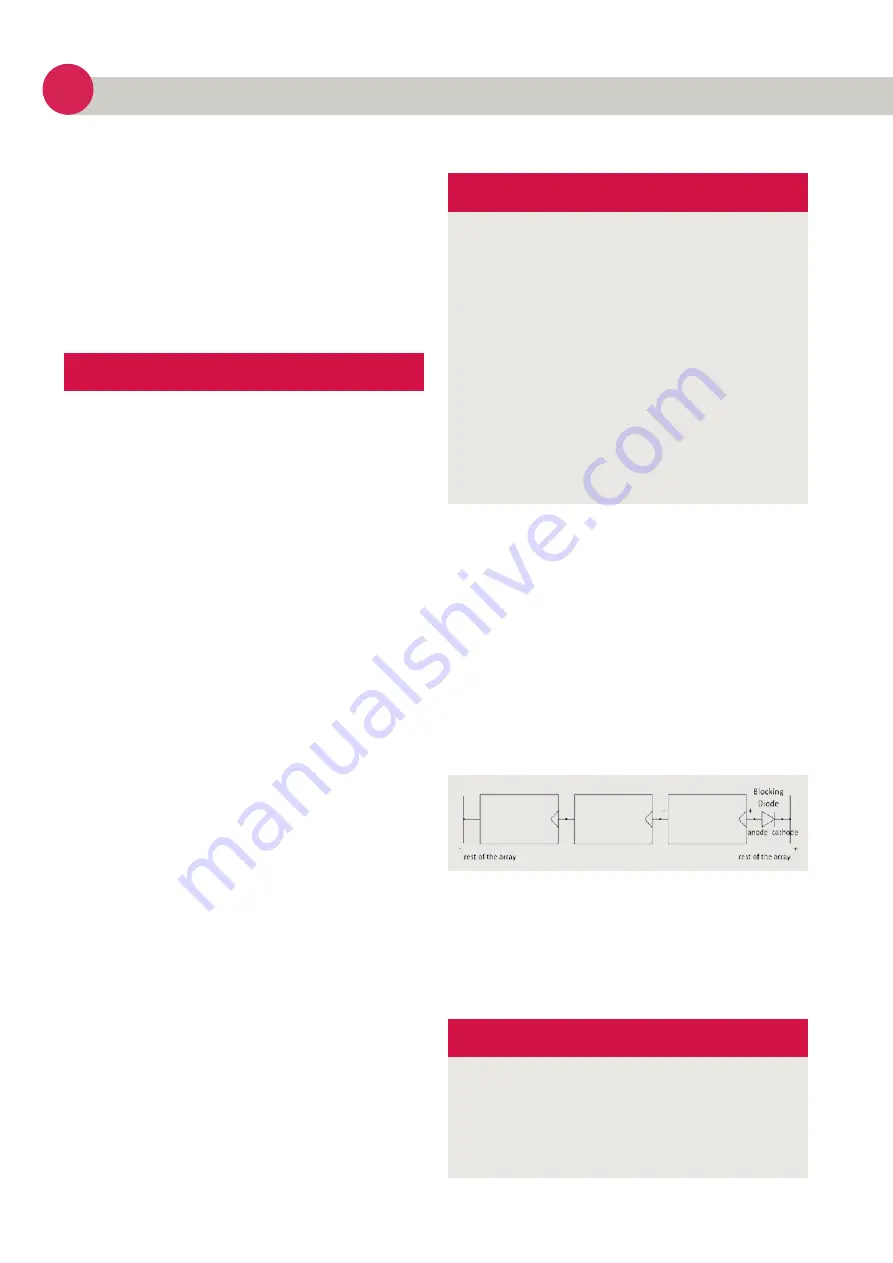

Series connection

In case it is necessary to connect module strings in parallel in

addition to the series connection, undesired reverse currents

can occur.

In the case of reverse currents, not only modules can be

damaged (caused by module defects, earth faults or insulation

faults) but also personal injury and property damage.

IMPORTANT SAFETY INFORMATION !!

If the module strings are connected in parallel, external

diodes (blocking diodes adapted to the output) are requi-

red because the internal electronics adapted to the modle

output cannot regulate the current flow, when individual

module strings are shaded in the parallel connection.

Failure to observe this can damage the solar modules and

internal electronics, resulting in personal injury and proper-

ty damage.

Ensure compliance with the maximum reverse current load

specified in the data sheet !

In order to limit or prevent the reverse currents that occur,

we recommend the following technical solutions:

Series connection

1) Design with a limited number of parallel-connected

strings:

»

To limit the current, a maximum of two module strings

can be operated in parallel on an inverter or an MPP

tracker.

»

If more than two strings are operated in parallel on an

MPP tracker or an inverter input, the use of blocking

diodes adapted to the power to protect against reverse

currents is mandatory.

2) Design with string protection:

»

Secure modules per string on the plus and minus side.

Use gPV fuses in accordance with IEC 60269-6. Observe

the number of strings permitted in accordance with the

specifications of the respective string fuse manufacturer

and the technical guidelines.

IMPORTANT SAFETY INFORMATION !!

If the inverter does not have integrated reverse current

protection, this must be provided externally in form of a

blocking diode in the individual DC strings.

NOTE! When installing different product revisions, the

minimum permissible reverse current load applies.

Page 6

e