ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

24

www.energie.pt

Upon the initial installation and before establishing any hydraulic connection of the heating circuit to the Combi

Block, the whole hydraulic installation must be cleaned to remove any dirtiness, remains of material and similar

impurities.

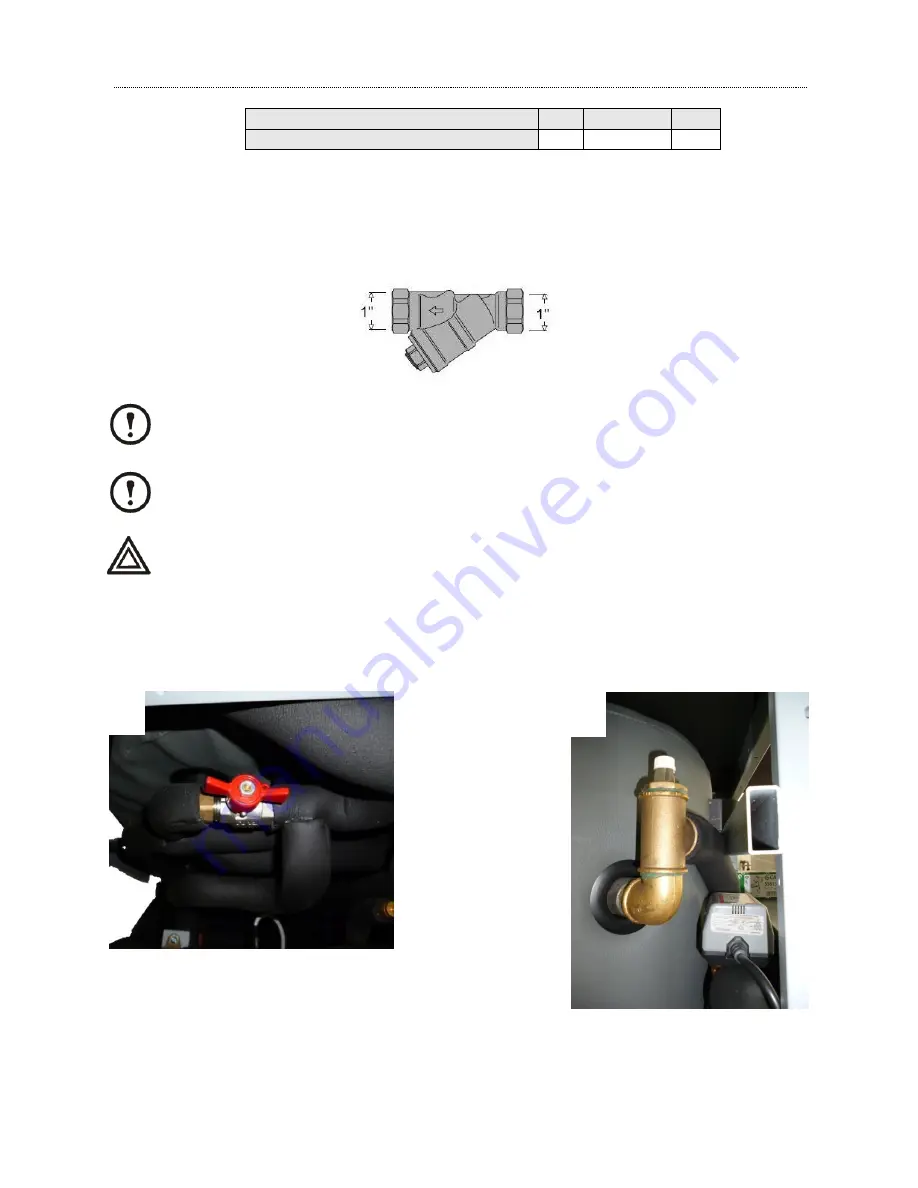

After carrying out the cleaning of the circuit, connect it to the Combi Block, placing, without fail, a filter at the return

water inlet as an accumulation of residues in the condenser may bring about a system malfunction. The figure below

illustrates the type of filter that is supplied.

When installing the Combi Block along with another heating device we must bear in mind and place the

Combi Block in parallel with the existing equipment.

Firstly, preferably choose heat emitters with a large exchange surface (radiant flooring, radiators,

convectors, ventilo-convectors) as they allow distribution at a low temperature and better performances

to be obtained.

It is compulsory to apply an anticorrosive additive (stabilising liquid) on the hydraulic circuit to prevent

clogging, electrolysis phenomena and noise on the circuit.

When the circuit is properly connected, fill the hydraulic circuit

(open the “cut

-

off” valve on the botton

part of the

unit, number

1

on image below) and as this operation is being undertaken, you must purge (on the manual vent,

number

2

) all the circuits, ensuring that you eliminate all the air pockets from the installation.

As a precaution, you must carry out a leak test. The test must be carried out with pressure 1.5 times the working

pressure.

Combi

6

12 / 12 HT

16

Minimum flow at the condenser (m

3

/h)

0,7

1,0

1,5

1

2