ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt

7

The temperature difference brought about by the previous factors ensures that the fluid will change to vapour state

inside the panel.

The compressor aspirates the refrigerant fluid (vapour) of the panel, raising the pressure and temperature thereof,

which is transmitted to the water circuit by way of a heat exchanger.

The Exchanger is located inside the cabinet (Combi Block), providing heat to the water which is inside.

When the refrigerant fluid reaches the expansion valve it is at its liquid phase and the load loss owing to

strangulation reduces the pressure and the fluid is re-prepared for entry into the panels.

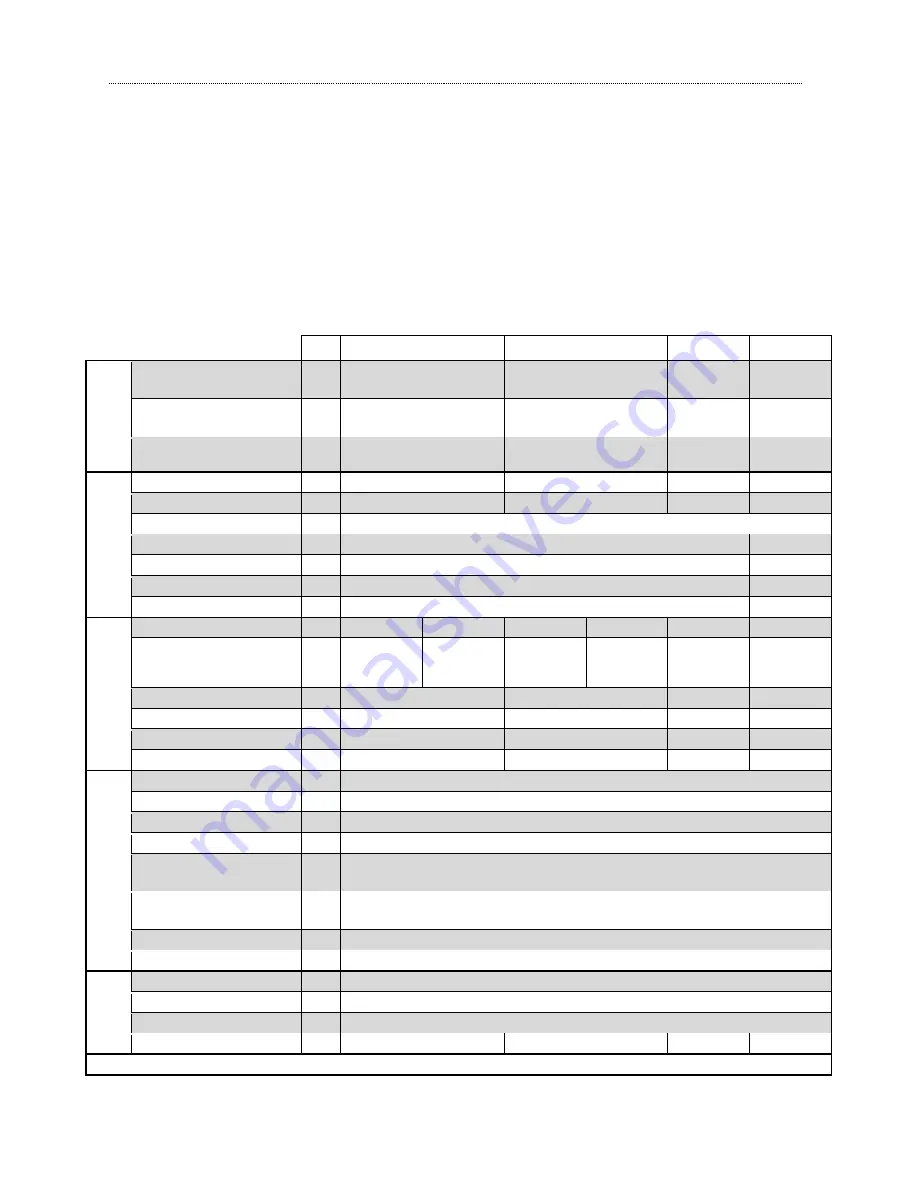

4.2.

Technical Specifications

The

ENERGIE

Combi Systems are presented on the market in a range of 4 models in accordance with the table

below:

Un.

Combi 6

Combi 12

Combi 16

Combi 12HT

Th

e

rm

o

d

yn

am

ic

So

lar

Pan

e

ls

Quantity

6

12

16

12

Weight

kg

48

96

128

96

Exposed Capture Surface

m²

9,6

19,2

26,6

19,2

R

e

fr

ig

e

ran

t

Type

R 407C

R 407C

R 407C

R 134a

Amount (pre charge)

kg

1,6

2

2,5

2

Test Pressure

bar

30

LP Switch Open Value

bar

1

0,3

LP Switch Close Value

bar

2

1,7

HP Switch Open Value

bar

28

21

HP Switch Close Value

bar

23

16,0

El

e

ctr

ic

al

Data

Single Phase / Three Phase

1P+N

3P+N

1P+N

3P+N

1P+N

3P+N

Power Supply

220-240V~

50Hz

380-420V~

50Hz

220-240V~

50Hz

380-420V~

50Hz

220-240V~

50Hz

380-420V~

50Hz

Rated Power Consumption* kw

1,2 - 2,2

1,9 - 3,1

3,2 - 5,2

1,7 - 3,0

Auxiliary Heater 1

kw

4,5

4,5

6

6

Auxiliary Heater 2 (DHW)

kw

1,5

1,5

1,5

1,5

Output Capacity

kw

4,9 - 9,7

9,2 - 16,7

14,2 - 24,2

7,8 - 15,8

D

o

m

e

sti

c Hot

Wate

r

Material

Stainless Steel

Capacity

l

200

Safety Thermostat Activ.

°C

80

Cathodic Protection

Magnesium Anode

Maximum Running

Pressure

bar

7

Maximum Running

Temperature

°C

80 (safety thermostat)

Expansion Vessel

l

5

Inlet / Outlet Connections

inch

3/4"

H

e

ating

Heating Pipe Diameter

mm

28

Pressure Safety Valve

bar

7

Expansion Vessel

l

10 (installations<120l)

Nominal Flow

m³/h

0,7

1,1

1,5

1

*Rated Power Consumption Without Auxiliary Heater 1 and 2