Operating Manual

96

Arc fault

protection ZŁ-4A; (07.2019)

15.3. Detection and elimination of the damage

The device possesses the self-diagnostics system that provides instantaneous signaling

of most of inner failures. After detecting a failure by the self-diagnostics system or by the

personnel it is necessary to describe symptoms of the failure and to consult them with the

representative of the producer service in order to obtain instructions for further procedure. It

is not recommended to make any repairs by the user without previous arrangement with the

producer of the device.

16. Storing

Transport packaging should have the same vibrations and strokes endurance as it is

specified in standards PN-EN 60255-21-1:1999 and PN-EN 60255-21-2:2000 for the sharp-

ness of the class 1.

The device delivered by the producer should be unpacked carefully not with use of too

much strength and not adequate tools. After unpacking it should be visually checked if the

device has no external damage.

The device should be stored in a dry and clean place. The temperature of the storage is

in the range from

−

25

C up to +70

C.

Relative humidity should be in such a range that condensation and hoarfrost would not

occur.

The devices should be installed at their workplaces about 2 hours before supplying. It is

necessary to equalize temperature and to avoid humidity and condensation.

17. Utilization

If it is necessary to disassemble the device (and eventually remove it) as the result of a

damage or the end of its operation life time, all the supplying and measurement units and

other connections should be switched off before.

The disassembled device should be treated as electronic scrap which undergoes appro-

priate regulations concerning waste management.

Summary of Contents for ZL-4A

Page 24: ...Operating Manual 24 Arc fault protection ZŁ 4A 07 2019 Fig 5 ZŁ 4A JC dimensions ...

Page 25: ...Operating Manual Arc fault protection ZŁ 4A 07 2019 25 Fig 6 ZŁ 4A JP dimensions ...

Page 26: ...Operating Manual 26 Arc fault protection ZŁ 4A 07 2019 Fig 7 ZŁ 4A JW dimensions ...

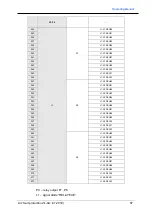

Page 61: ...Operating Manual Arc fault protection ZŁ 4A 07 2019 61 Fig 36 Page 2 STATUS using ...