EK-Pak Owner and Installation Manual

EK-Pak Owner & Installation Manual First Edition December 2002

17

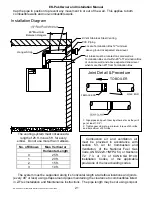

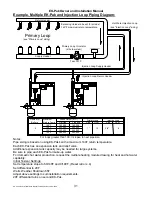

Gas Flow Pressure Drop and Regulator Lock Up Check:

This test is very important and will tell you whether your piping system is properly sized for the

maximum firing rate and whether your regulator is working properly.

•

Record and total up the firing rates of all appliances in the building.

•

Install a manometer at the inlet side of the gas valve.

•

Turn on enough appliances to draw 50% of the maximum firing rate for the entire

building.

•

The manometer pressure reading should be about 11” for Propane and about 7” for

Natural Gas.

•

Turn on all appliances to draw 100% of the maximum firing rate for the entire building.

•

The manometer pressure reading should not drop more than 20% below the 50% draw

flow pressure

o

Should not decrease more than about 2” for Propane or 1.5” for Natural Gas.

If decrease is too much, then the piping/fittings/valves are undersized.

•

Turn off all appliances, and shut off all pilot lights.

•

The manometer pressure reading should not increase more than 20% over the 50%

draw pressure

o

Should not increase more than about 2” for Propane or 1.5” for Natural Gas.

If increase is too much, then possibly the regulator is not working properly.

Record firing rate

Record Manometer Reading

Running at 50% Firing Rate

Running at 100% Firing Rate

All gas flow stopped

Stopped

Example:

•

There are four gas-fired appliances in the building. A water heater rated at 35,000

Btu/hr, a gas fireplace rated at 25,000 Btu/hr, a gas range rated at 65,000 Btu/hr, and

an EK-Pak heating module fired at 185,000 Btu/hr. The water heater, the fireplace, and

the range add up to 125,000 Btu/hr. Adding the firing rate for the EK-Pak heating

module gives a total of 310,000 Btu/hr.

•

Turn on just the EK-Pak to get 185,000/310,000 = 60%.

•

While running on natural gas, the EK-Pak gas valve inlet pressure is reading 6.5” w.c.

•

Turn on the other three appliances and the EK-Pak gas valve inlet pressure drops to

5.0” w.c., which is just within the limit.

•

Turn off all the appliances by closing their manual shutoff valves.

•

The EK-Pak gas valve inlet pressure increases to 8” w.c., which is just within the limit.

From this test, we can say the piping is properly sized and the main gas regulator is working

properly

Z4

Z1