EK-Pak Owner and Installation Manual

EK-Pak Owner & Installation Manual First Edition December 2002

5

TABLE OF CONTENTS

Page Topic

Page Topic

1

Please Read This First

18

Plate Heat Exchanger

4

Record of Installation

19

Flush, Purge, and Fill System with Water

5

Table of Contents

19

Heating module Water Treatment

6 Overview

19 Anti

Freeze

6 Features

19 Winterizing

7

EK-Pak Technical Specifications

20-21

Combustion Air and Venting

7

Versatile Heating Output

22

Prepare for Start Up

7

Theory of Operation

22

Start Up Procedure

8

Typical Control Sequence

23

Start Up

9

Quick Setup Guide

24

Annual Maintenance

9

Receiving and Unpacking

24-25

Trouble Shooting

10

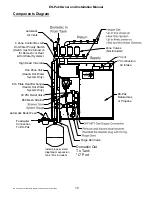

Components Diagram

26

EK-Pak Hot Water Knockdown

11

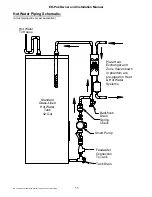

Hot Water Piping Schematic

27

Gas Protection Kit

12

Location and Clearances

28

Example Baseboard Sizing

12

General Assembly

29

Example Air Handler Sizing

12

EK-Pak Mounting

30

Example Piping Diagram for Baseboard,

Domestic and Radiant.

13

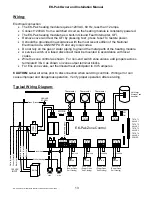

Wiring

30

Example Wiring Diagram for Baseboard,

Domestic and Radiant

13

Typical Wiring Diagram

31

Example Piping Diagram for Multiple EK-

Paks and Injection Loop.

14

Gas Piping Systems

32

Example Wiring Diagram for Air Handler with

Electronic Fan Center

16

Gas Pipe Leak Testing

33

Example Wiring Diagram for Air Handler with

Mechanical Relay Fan Center

17

Gas Flow Pressure Drop

34

Category III Venting (Z-Vent)

18

Zone Control

35

Replacement Parts

18

Hot Water Storage Tank

Inside

Back

Cover

Limited Lifetime Warranty

Back

Cover

Warranty Transfer Agreement