4S-SERIES PRESSURE EXCHANGER ENERGY RECOVERY DEVICES

Energy Recovery, Inc.

6

ERI Document Number 80022-01-04

installed, the main high-pressure (HP) pump is sized to equal the SWRO permeate flow plus a

small amount of bearing lubrication flow, not the full SWRO feed flow. Therefore, PX energy

recovery technology significantly reduces flow through the main HP pump. This point is

significant because a reduction in the size of the main HP pump results in lower capital and

operating costs. In a typical SWRO system with a PX unit operating at 40% recovery, the main

HP pump will provide 41% of the energy, the booster will provide 2% and the PX unit will

provide the remaining 57%. Since the PX unit uses no external power, a total power savings of

57% is possible compared to a system with no energy recovery.

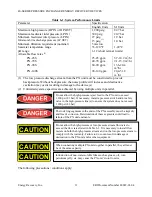

Table 4-1. Typical SWRO System Flows and Pressures

STREAM DESCRIPTION

FLOW RATE

GPM / M3/HR

PRESSURE.

PSI / BAR

A

Seawater Supply

133 / 30.2

25 / 1.7

B

LP IN to PX Unit / Seawater

78 / 17.7

25 / 1.7

C

Main HP Pump outlet

55 / 12.6

1000 / 69

D

HP OUT of PX Unit / Seawater

78 / 17.7

957 / 66

E

Booster Pump Outlet / Seawater

78 / 17.7

1000 / 69

F

SWRO Feed Stream

133 / 30.2

1000 / 69

G

HP IN to PX Unit / Reject

80 / 18.2

971 / 67

H

LP OUT of PX Unit / Reject

80 / 18.2

15 / 1.0

I

SWRO Product Water

53 / 12.1

5 / 0.3

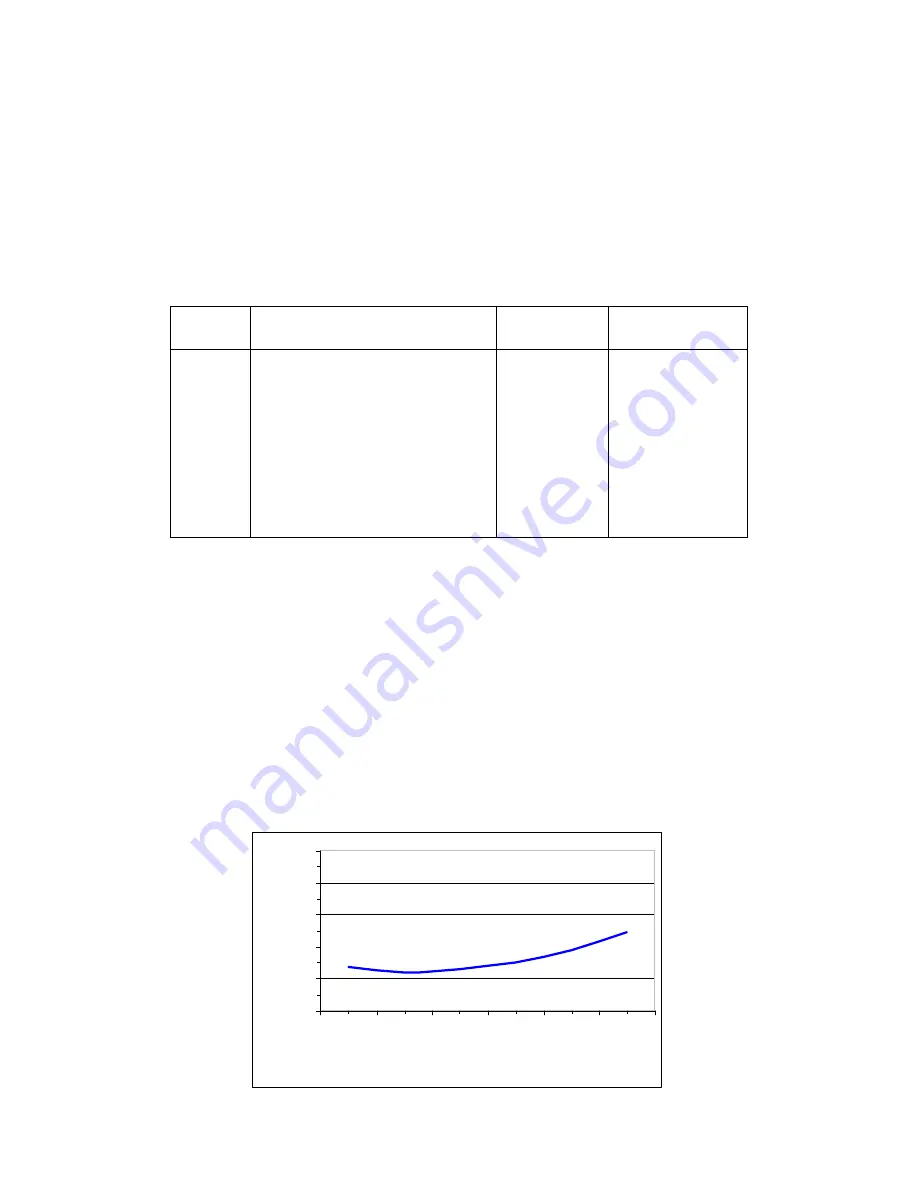

An SWRO system with ERI energy recovery device(s) can operate efficiently at low recovery

rates because PX units replace all of the reject-brine flow with a nearly equal volume of feed-

seawater at up to 97% efficiency. One advantage of operating at lower recoveries with PX

energy recovery devices is that a lower operating pressure is required to produce a given amount

of permeate. Since the main high-pressure-pump flow rate always equals the permeate flow rate

plus the hydrodynamic bearing lubrication flow rate, low energy consumption at low recovery

rates is possible with ERI technology. The overall energy consumption of an SWRO plant using

the PX energy recovery device(s) typically has a minimum point at recovery rates of between 30-

40%. Outside this recovery range, the plant will start to consume slightly higher amounts of

power. Figure 4-3 illustrates the relationship between SWRO recovery rate and overall SWRO

power consumption.

2.0

2.2

2.4

2.6

2.8

3.0

25%

30%

35%

40%

45%

50%

Recovery

E

n

er

g

y

(

k

Wh

/m

3)

Figure 4-3. SWRO Plant Energy

Consumption as a Function of Recovery Rate