17

4. Installation of Boiler Components

With the vessel in place, you are ready to attach the vessel panels and insulation, the wire

harness and controls, the optional domestic coil, and the burner/preheater assembly. Then,

you will install the fuel tubing from the pump discharge to the preheater. Finally, your hydronics

professional will connect the hydronic piping system to the boiler

– and fill the system.

4.1 Vessel Panel and Insulation Assembly

Install the vessel panels and insulation as follows:

1. Open the box containing the insulation, panels, and hardware.

2. Wrap the insulation around the boiler vessel. Use the ribbon provided to secure the

insulation around the vessel. Install the insulation for the front panel. Note: Make sure to

cut out the insulation for ports and drains as needed. On front panel, make sure that the

insulation is cut out to provide a view of the ASME boiler plate.

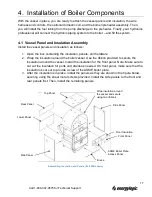

3. After the insulation is in place, install the panels as they are shown in the figure below,

securing using the sheet metal screws provided. Install the side panels to the front and

rear panels first. Then, install the remaining panels.

Side Panel

Wrap insulation around

the vessel and secure

using two ribbons.

Front Panel

Front Insulation

ASME Boiler Plate

Access Panel.

Brace

Side Panel

Rear Panel

Lower Panel

Top Panel

Assembling Insulation and Panels (EL-200B shown)

Call 1-

800-347-9575

for Technical Support