29

Call 1-

800-347-9575

for Technical Support

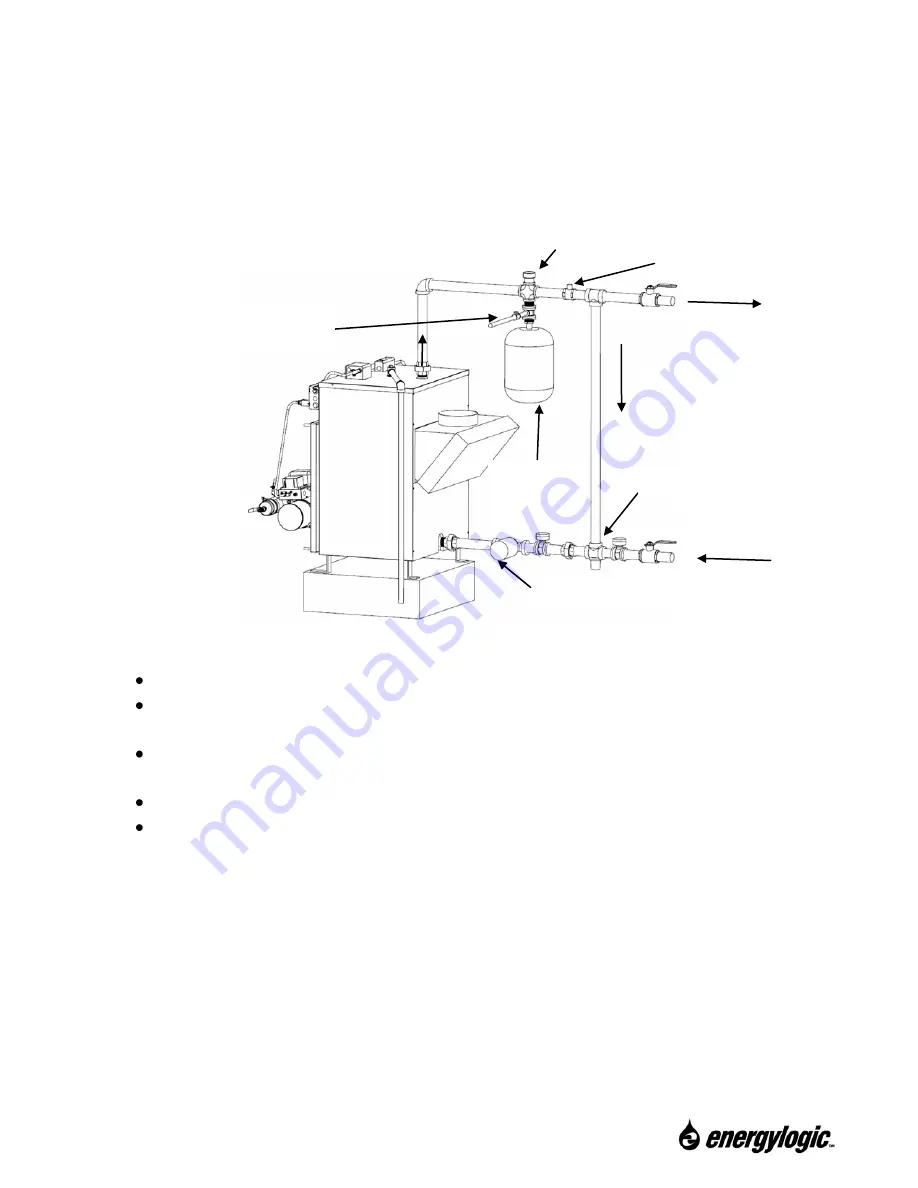

4.8.2 Hydronics Set Up

The EL boiler package provides controls to monitor water level and temperature, but does not

provide all the necessary hydronics components. Closed-loop boiler systems typically have the

following components installed on the water side (actual components should be determined by

the hydronics expert):

Circulator pump

– sized for desired flow rate, modulating actuator and pocket stat.

Air diaphragm expansion tank

– used to prevent system pressure spikes as the loop

water temperature increases. Size this accordingly based on the BTU net output.

Air/water separator

– used to remove air from the initial water charge in a closed-loop

system.

Water make-up valve

– provides make-up water for small losses in the loop over time.

Miscellaneous valves and gauges. Check valves and isolation valves are essential to

ensuring proper water flow and serviceability. Gauges are used to monitor the system.

Air Separator

Check Valve

System Out

Recirc. Loop

140°F Mixing Valve

Circulator Pump

Diaphragm

Expansion

Tank

Make-up

Water Supply

System Return

Hydronics System Example.