30

Call 1-

800-347-9575

for Technical Support

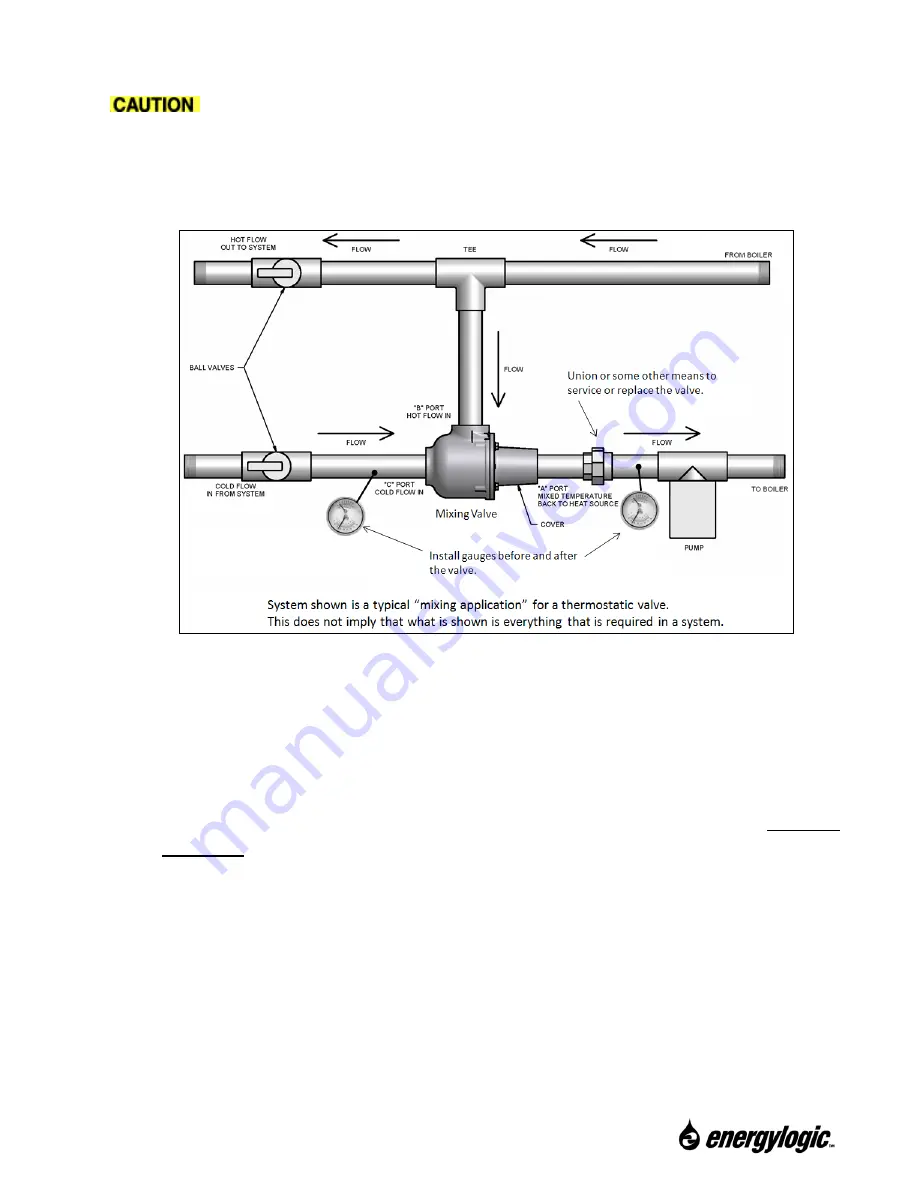

4.8.3 Boiler Mixing Valve Set Up

A thermostatic mixing valve is highly recommended as one means of assuring that

the water returning to the boiler is consistently above the minimum required temperature of

140°F. This valve, along with circulation control based on a minimum circulating water

temperature will protect the boiler from cold water. EnergyLogic offers boiler mixing valve kits.

The recommended installation for the valve is per the following diagram:

Boiler Mixing Valve Arrangement.

4.9 Filling the System

1. When the boiler system piping is complete, add heating-grade antifreeze into the vessel

through the gauge port on the top prior to filling the system with water. A 25% to 50%

solution is typical; however, the climate of use will dictate the freezing protection

required. It is recommended that the percent solution used be based on the minimum

necessary for freeze protection. The antifreeze must be propylene-based, hydronic

grade for heating systems, rated for high temperature operation. RV grade solution will

not hold up, and should never be used.

2. For reference, following are the vessel capacities for the various models.

a. EL-200B

30 gallons

b. EL-375B

43 gallons

c. EL-500B

52 gallons

Additional capacity for the piping system must be estimated specific to the application.

3. Inspect all connections for leaks.