54

Call 1-

800-347-9575

for Technical Support

8.5.3 Fuel Oil Filter Replacement

How often?

Every 800

– 1000 hours of operation, or when the vacuum gauge reads 5 inches Hg higher

than readings taken with a clean filter.

Tools Required:

Safety glasses, rubber gloves.

Replacement Parts:

EnergyLogic Spin-On Fuel Filter (PN 20270185)

Spec: Hydraulic/140 Micron/Metal Mesh, max. working pressure 200 psi, 25 GPM capacity.

Note: Use only genuine EnergyLogic parts to avoid damage and maintain UL status.

Procedure - All Models:

1. Wear all safety equipment.

2. Close the Fire-Stop Valve or ball valve(s) at the filter head.

3. Spin the Fuel Filter off the Filter Head Assembly - counter-clockwise. Dispose of the fuel

filter properly.

4. Clean any debris from the filter head assembly.

5. Fill new Fuel Filter with non-synthetic ATF or pre-filtered used oil to quicken the priming

process. Do not use new oil or synthetic ATF to fill the filter. Apply a thin film of oil to the

gasket.

6. Spin the Fuel Filter onto the Strainer Housing - clockwise. Hand-tighten the filter.

Record the meter hours and date on the new filter.

7. Open Fire-Stop Valve or ball valve.

8. Refer to Section 7.4.1

“Fuel System Priming” for the priming procedure to ensure no air

remains in the fuel system.

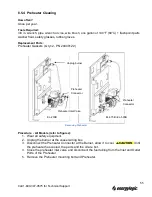

Fire stop valve open Fire stop valve closed

Filter Head Assembly

Fuel Filter

Fire Stop Valve

Filter Head and Valves