60

Call 1-

800-347-9575

for Technical Support

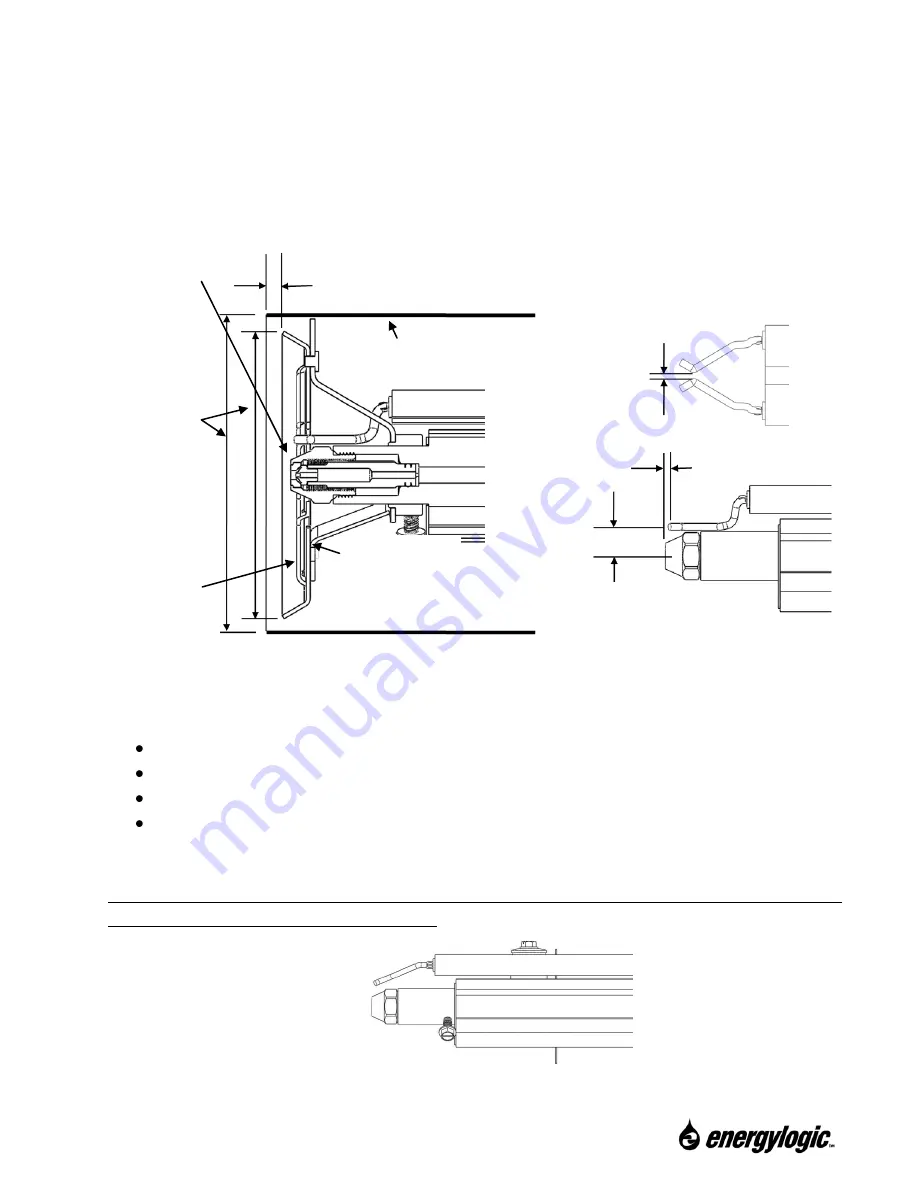

8.5.6 Retention Head and Electrode Settings

How often?

Once per year (refer to 8.5.5, Nozzle Line Cleaning)

Procedure

- All Models.

NOTE:

There are two Electrode/Retention Head designs: one where the

electrodes wires make two 90 degree bend

s (called “Double Bend”), and one with a single angled

bend. The “Single Bend” design only goes with Retention Heads with the added center cutout.

Refer to Section 8.5.5 for removal of nozzle block and electrode assembly.

Inspect the

locations of the electrode components. If adjustments are necessary, use needle-nose pliers to

carefully adjust electrode wires. Use the following specifications:

The Electrode Gap:

3/32” (2.4 mm).

Electrode Tips must be 1/1

6” (1.6 mm) behind the tip of the Nozzle.

Nozzle protrudes approximately 1/8

” (3 mm) beyond Retention Head vanes.

Vertical location of electrode wires: 7/16” (1.6 mm) from center nozzle to wires. Make

sure that there is a gap between the electrode wires and the nozzle. Make sure there is

a gap between the retention head inner diameter and the electrode wires.

NOTE:

For the

“Single Bend” electrode, the same settings are used, but the electrode wires

come down at an angle, as shown below.

3/32” (2.4

mm) Gap

1/16” (1.6 mm)

(Electrode behind tip)

1/16” – 1/8” (Flame Retention Head recessed inside Air Tube)

(1.5

– 3 mm)

Retention Head

Air Tube

Center

Retention

Head

within Air

Tube.

Nozzle must

extend

approx. 1/16

to 1/8” (1.5 to

3 mm) beyond

air vanes.

Air Vanes

Settings for Retention Head & Electrodes

– “Double Bend” Electrodes

7/16” (11 mm)