64

Call 1-

800-347-9575

for Technical Support

8.5.8 Air Compressor Maintenance

How often?

Once per year. More often for dusty conditions.

Tools Required:

1/8 inch Allen wrench, 7/16 inch wrench, flat-blade screwdriver, EnergyLogic Air Compressor

Pressure Gauge Kit (PN 05000092), Gast compressor cleaning fluid, shop towel, rubber

gloves, safety glasses.

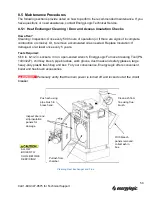

Procedure - All Models (refer to figures):

1. Wear all safety equipment.

2. Replace the compressor air filter annually

(PN 20210112).

3. Check the air compressor output by using

the EnergyLogic compressor test kit (PN

14012100). Remove the copper tubing

from the outlet of the compressor and from

the bulkhead fitting on the burner. Attach

one of the tubes in the

kit to the 3/16”

outlet fitting on the compressor, and the

other tubing to the bulkhead fitting. Attach

both tubes to the gauge in the kit. Be

careful to not make kinks in the tubing.

4. Start the burner by moving the wall thermostat above room temperature and note the air

compressor output on the gauge. If the gauge reading is in the 9-11 PSI range for the

EL-200B or in the 13-15 PSI range for the EL-375B or EL500B, the air compressor is

operating as designed and no further maintenance is required. Remove the test kit and

reinstall the

3/16” tubing, for normal operation.

5. If the gauge reading is below the normal range, check/do the following:

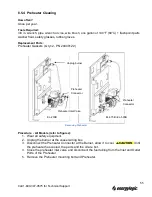

A. Coupling

1. Inspect the air compressor coupling by unplugging the burner, loosening the Ignition

transformer screws, then lifting it back on its hinge.

Coupling to Compressor

2. Spin the squirrel cage and note if the coupling slips on the burner motor or air

compressor shaft.

3. If the coupling is slipping, use a 1/8 inch Allen wrench to tighten the set screw.

4. If the set screws are tight, inspect the metal ends of the coupling for damage. Replace

as necessary.

Air Compressor

Coupling

(Parts removed from

illustration for clarity.)

Set Screws

Remove Filter

Inlet

3/16” Outlet Fitting