8

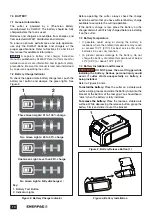

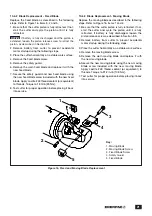

2.6 Dimensions

Dimension

in

mm

C

A

B

A

19.8

504

B

6.9

176

C

13.9

354

Product specifications are subject to change without notice.

3.0 CONFORMANCE TO NATIONAL AND

INTERNATIONAL STANDARDS

Enerpac declares that this product has been

tested and conforms to applicable standards

and is compatible with all CE requirements.

A copy of an EU Declaration of Conformity is

enclosed with each shipment of this product.

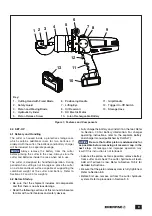

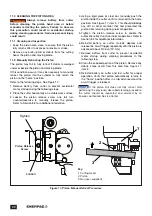

4.0 DESCRIPTION

The Enerpac cordless bar cutters, models EBC20B and

EBC20E, are designed to cut round, square or flat metal

bars and other similar items.

These cutters contain t

wo blades, one fixed and one

moving. The moving blade is actuated by a hydraulic

cylinder.

Power is supplied by an 18 or 20 volt lithium-ion battery

(varies by region). The battery powers a DC electric

motor, which drives a small hydraulic gear pump. The

pump provides oil flow to the hydraulic cylinder, which

advances the cylinder piston.

A hydraulic reservoir with built-in rubber diaphragm

provides a constant supply of oil to the pump, regardless

of tool orientation or the amount of piston extension.

A trigger-style on-off switch, mounted on the cutter grip,

starts and stops the electric motor. The trigger must

remain pressed during the cutting process.

An automatic retract feature moves the piston to the

fully retracted “home” position when the piston reaches

its full stroke and the trigger is released.

A built-in blade safety guard provides protection from

splintered material during cutting and helps prevent

contact with the blades.

The rotatable cutting head can be turned 360 degrees,

allowing it to be positioned as needed for added

convenience.

See Figure 1 for a description of cutter major features

and components. Refer to Sections 2.1 through

2.6 of this manual for maximum cutting capacities,

specifications and dimensions.

5.0 RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If shipping

damage is found, notify carrier at once. The carrier

is responsible for all repair and replacement costs

resulting from damage in shipment.

5.1 Documents and Accessories

The following documents and accessories are included

with the cutter:

• Instruction Sheet

• Declaration of Conformity

• Protective Storage Case

• Allen Wrench – 8 mm

• 2 x Battery 20V-5Ah (Model EBC20B only)

• 2 x Battery 18V-5Ah (Model EBC20E only)

• Charger, 115V (Model EBC20B only)

• Charger, 230V (Model EBC20E only)

Summary of Contents for EBC20B

Page 25: ...25 Notes...

Page 26: ...26 Notes...

Page 27: ...27 Notes...

Page 28: ...199 Gateway Ct Columbus WI 53925 USA www enerpac com Made in Italy WWW ENERPAC COM...