9

1 2 3

4

6

7 8

9

5

13

10

11

12

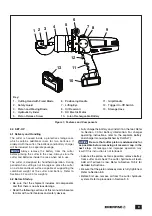

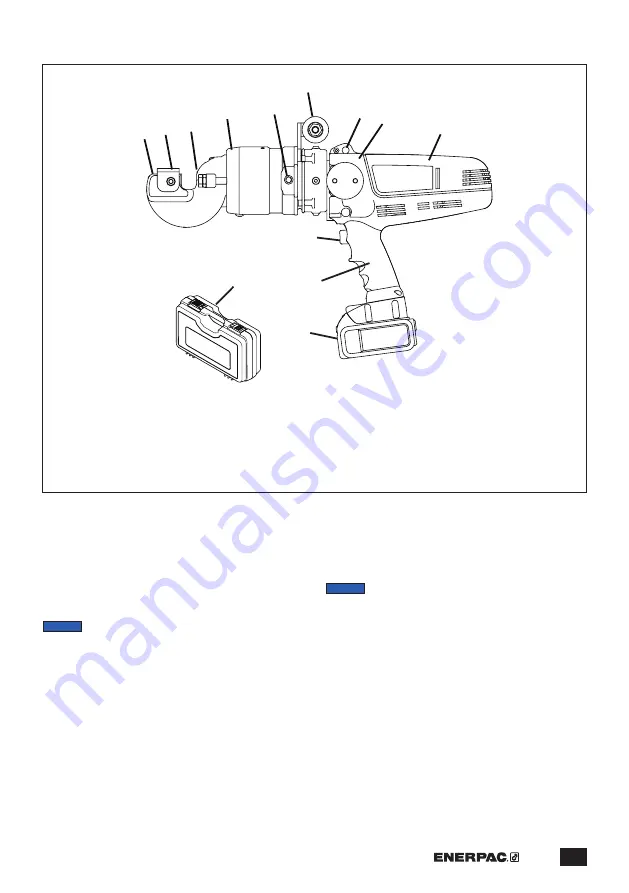

Figure 1, Features and Components

Key:

1. Cutting Head with Fixed Blade

2. Safety Guard

3. Piston and Moving Blade

4. Hydraulic Cylinder

5. Piston Release Screw

11. Grip/Handle

12. Trigger On-Off Switch

13. Storage Case

6. Positioning Handle

7. Lifting Eye

8. Oil Reservoir

9. DC Electric Motor

10. Li-Ion Rechargeable Battery

6.0 SET-UP

6.1 Delivery and Handling

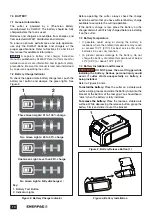

The cutter is housed inside a protective storage case

which contains additional room for two batteries. If

ordered with the cutter, the batteries and battery charger

will be included in a separate package.

NOTICE

Always remove the battery from the cutter

before placing the cutter in the case. Always store the

cutter and batteries inside the case when not in use.

The cutter is designed for handheld operation. During

periods when cutting is not in progress, place the cutter

on a stable and level surface capable of supporting the

combined weight of the cutter and battery. Refer to

Sections 2.2 and 2.4 for weights.

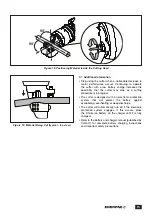

6.2 Before Startup

• Be sure that the shipment includes all components

and that there is no obvious damage.

• Read the following sections of this manual to become

familiar with cutter features and safety devices.

• Fully charge the battery and install it on the tool. Refer

to Section 7.0 for battery information. For charger

operating instructions, refer to the separate battery

and charger manual (published by D

e

WALT).

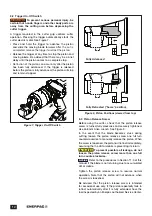

NOTICE

Be sure that cutter piston is advanced as far

as possible before removing oil reservoir cap in the

next step.

Oil leakage and improper operation may

result if this instruction is not followed.

• Advance the piston as far as possible, remove battery

from cutter and check the cutter hydraulic oil level.

Add oil if oil level is low. Refer to Section 10.5.2 for

detailed instructions.

• Be sure that the piston release screw is fully tightened.

Refer to Section 8.3.

• Before first use, remove air from the cutter hydraulic

system. Refer to procedure in Section 9.3.

Summary of Contents for EBC20B

Page 25: ...25 Notes...

Page 26: ...26 Notes...

Page 27: ...27 Notes...

Page 28: ...199 Gateway Ct Columbus WI 53925 USA www enerpac com Made in Italy WWW ENERPAC COM...