11

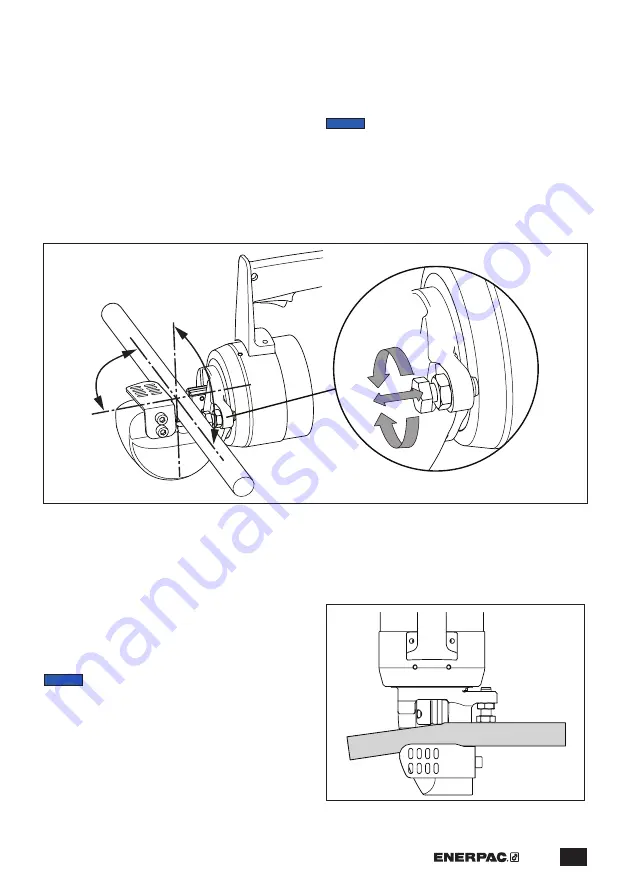

9.5 Positioning Material Inside the Cutting Head

Be sure that the piston and moving blade are located in

the fully retracted “home” position before placing any

material inside the cutting head. See Figure 7.

Position the material to be cut between the cutter

blades, so that it is perpendicular to the piston axis, as

shown in Figure 7. This will provide the best quality cut

while placing the least amount of load on the cutter.

Adjust the support bolt as needed. The head of the

support bolt should just touch the surface of the material

to be cut, when the item is positioned against the fixed

blade of the cutter.

After adjusting the support bolt, be sure that the support

bolt retaining nut is snug tight against the support

bolt mounting ear. This will help prevent support bolt

movement during cutting.

NOTICE

Be certain that the hardness, tensile strength

and diameter of the material to be cut do not exceed any

of the stated maximum limits.

Refer to

Section 2.1

of this

manual for additional information. Failure to observe this

instruction may result in poor cutting performance

and/or damage to the cutter.

90°

90°

Figure 7, Positioning Material Inside Cutting Head

Material Position (optimum)

Support Bolt

9.6 Cutting Procedure (typical)

1. Connect the cutter to the electrical outlet.

2. Be sure that the piston is in the “home” (fully retracted)

position. See Figure 3.

3. Be sure that the piston release screw is turned fully

clockwise. See Figure 4.

4. Place the material to be cut between the fixed and

moving blades. Refer to instructions in Section 9.5 for

additional information.

NOTICE

Position the item to be cut so that it is as

perpendicular as possible to the blades, as described in

Section 9.5. Positioning the material at an angle will

side-load the piston. Jamming and/or damage to the

cutter may result.

5. Be certain that hands, fingers or other body parts are

not inside the cutting head.

6. Press and hold the trigger to start the motor and begin

cutting.

7. After cutting is completed, wait until the piston

reaches the end of its stroke and then release the

trigger. Verify that the moving blade reverses direction

and moves fully into the “home” (fully retracted)

position.

Figure 8, Material Being Cut (typical - top view)

Summary of Contents for EBE26

Page 23: ...Notes...

Page 24: ...WWW ENERPAC COM...