19

1. Be sure that the cutter piston is fully retracted. If not, start

the cutter and cycle the piston until it is fully retracted.

NOTICE

If the piston will not retract in step 1, move the

piston release lever to position 2 to manually retract the

piston. Refer to instructions in Section 8.4. Also see

Figure 8.

2. Disconnect cutter from AC power supply to prevent

accidental motor start-up during the following steps.

3. Place the cutter horizontally on a stable work surface

with the handle facing upwards.

4. Open the cutter safety guard.

5. Remove the moving blade screws and blade holder.

6. Remove the worn moving blade and replace it with

the new moving blade.

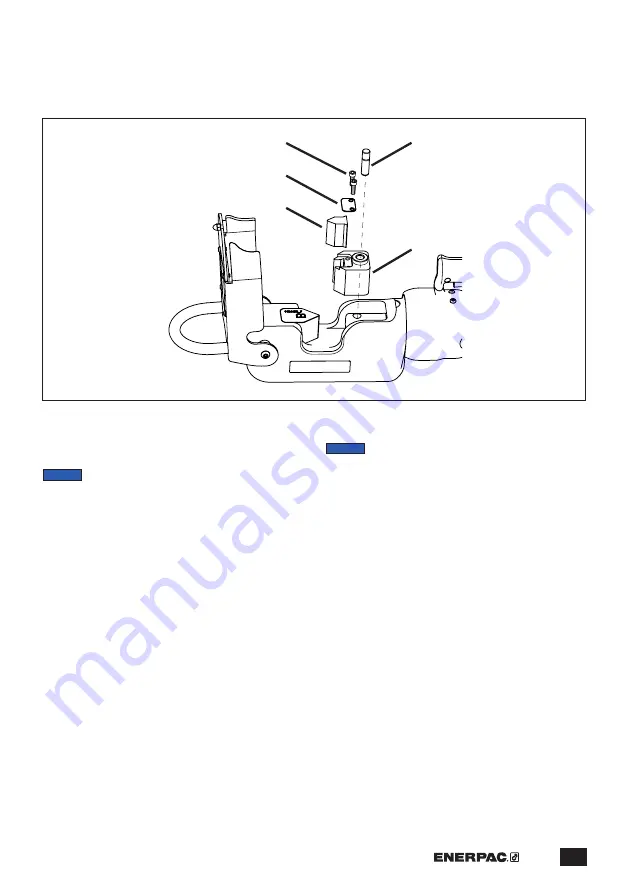

10.6.3 Blade Replacement - Moving Blade

Replace the moving blade as described in the following

steps. Refer to Figure 14, items 1 through 5.

Figure 14, Moving Blade Replacement

1

2

3

4

5

Key:

1. Moving Blade Screws

2. Blade Holder

3. Moving Blade

4. Positioning Pin

5. Moving Blade Support

NOTICE

In some instances it is possible for the moving

blade to become wedged into the moving blade support.

If needed, remove the positioning pin, remove the

moving blade support and pry or tap out the moving

blade from the blade support.

7. Secure the new moving blade with the new moving

blade screws included with the new moving blade

and blade holder. Apply Loctite 243 thread sealant (or

equivalent) to the screw threads. Torque to 91 in-lb

[10 Nm].

8. Close the cutter safety guard.

9. If piston release lever is in position 2, move lever

to position 1 to allow normal operation. Refer to

instructions in Section 8.4. Also see Figure 8.

10. Test cutter for proper operation before placing it

back into service.

Summary of Contents for ECCE26

Page 24: ...WWW ENERPAC COM...