16

10.5.3 Changing the Oil

NOTICE

The oil change procedure is very detailed and

will take a considerable amount of time. It should only

be performed by a trained technician at an Enerpac

authorized service center. Failure to properly perform

the procedure may result in incomplete filling of the

cutter oil reservoir, which could lead to cavitation, air

entrainment, reduced performance and pump damage.

Change the oil in the cutter hydraulic reservoir as

described in the following steps. Refer to Figures 13A

through 13E and Figure 14:

1. Before beginning this procedure, purchase a new

ECCE32 seal kit from your Enerpac authorized

service center or distributor. Some of the seals in this

kit will be used later in this procedure. Refer to the

cutter repair parts sheet for a description of seal kit

items.

2. Fill a clean oil dispenser with new Enerpac HF oil. Put

the dispenser aside for later use.

3. Operate the cutter and extend the piston all the way

forward.

4. Disconnect the cutter from the AC power supply to

prevent accidental motor start-up during the following

steps.

5. Place the cutter in the horizontal position, on a stable

and level work surface, with the oil reservoir cap and

diaphragm cover pointing upwards. Place a pan or

suitable container under the cutter to catch any

spilled oil.

6. To prevent contamination, remove any built-up dust

and dirt from the oil reservoir cap, diaphragm cover

and surrounding area.

NOTICE

A small amount of hydraulic oil leakage may

occur when the diaphragm cover and reservoir cap are

removed in the next step. Be prepared to catch this oil in

a pan or with a clean rag. Dispose of spilled oil in

accordance with all applicable laws and regulations.

7. Remove the oil reservoir cap and, using an adjustable

face spanner wrench, loosen and remove the

diaphragm cover.

8. Remove the diaphragm from the diaphragm opening.

9. Completely drain all old oil from the cutter, turning

it upside down and using a suitable oil extraction

system (used oil extraction pump) if necessary, so

that no oil remains in the cutter hydraulic reservoir.

NOTICE

Dispose of all used oil in accordance with all

applicable regulations and laws.

10. After all oil is evacuated, remove the three screws

for the standoff bracket and remove the standoff

bracket from the bottom of the cutter. See Figure 14.

11. Remove the directional control valve by removing

the four screws retaining it.

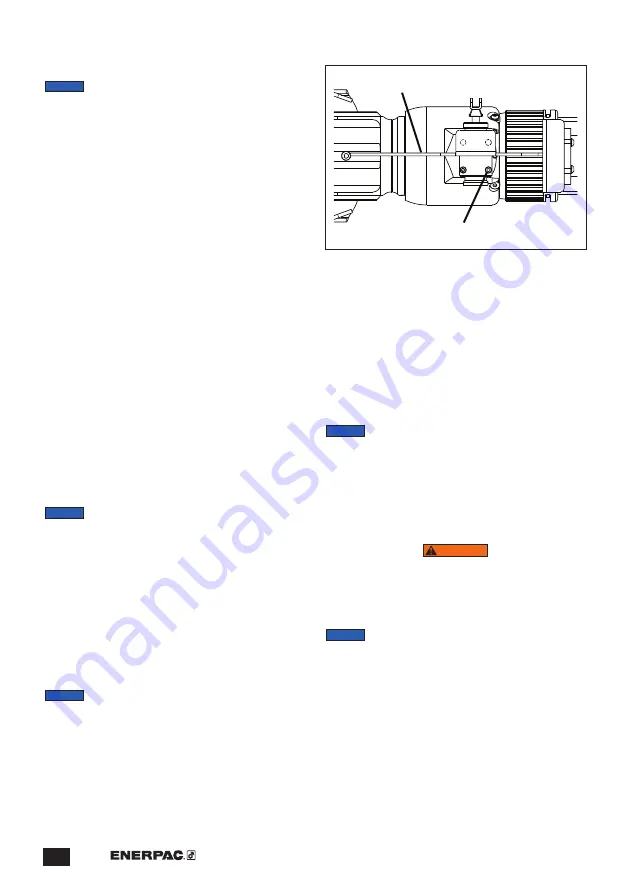

1

2

Figure 14, Standoff Bracket (1) and Directional

Control Valve Screws (2)

12. Position the cutter with the control valve oil holes

pointing straight down, and allow the remaining oil

to drain for 30 to 60 minutes. Toward the end of this

time, the end of the cylinder opposite the oil holes

can be elevated slightly to aid in the draining.

13. Reinstall the directional control valve, using the

new O-Ring seals from the ECCE32 seal kit (refer to

step 1 of this procedure).

14. Install the standoff bracket using the three screws.

Torque to 18 ft-lbs [25 Nm].

NOTICE

Use only new Enerpac HF oil in the following

step. Use of other oils may damage the cutter and may

invalidate the Enerpac product warranty.

15. Using the oil dispenser prepared in step 1, slowly

add new Enerpac HF oil through the oil drain/fill hole

and diaphragm opening until oil level is up to the top

of the drain/fill hole.

16. Install and securely tighten the oil reservoir cap.

NOTICE:

WARNING

To avoid serious personal injury, stay clear of cutting

head and blades during the following procedures.

Wear rubber gloves to prevent contact with oil. Wear

eye and face protection to avoid injury due to

splashing oil.

NOTICE

During the following steps, refer to Figure 5 for

directional lever positions.

17. Connect the cutter to the AC power supply.

18. Move the directional lever to position 2 (retract).

19. Cover the diaphragm opening with a rubber-gloved

hand to help prevent oil splashing.

20. Prime the pump by pressing and releasing the

trigger in short bursts. During this process, check

the oil level in the diaphragm opening and add oil

(as needed) to keep the reservoir filled. Failure to

keep reservoir full may result in cavitation and

pump failure. Pump is primed when piston starts

extending.

Summary of Contents for ECCE32

Page 23: ...Notes...

Page 24: ...WWW ENERPAC COM...