10

9.2 Operating Precautions

NOTICE:

WARNING

Failure to observe the following

precautions and instructions could result in death or

serious personal injury.

• Keep fingers, hands and other body parts clear of

the cutting head. Do not reach into the cutting area

during operation.

• Never place fingers, hands or other body parts

between objects being spread (such as a joint)

during the spreading process.

• When spreading, ensure that the spreading

wedges on the outside tips of the jaws fully engage

with the objects to be spread.

• Do not attempt to reposition the material being

cut while the tool is in operation. If repositioning is

required, stop the cutter.

• After cutting or spreading is complete, material

may fall. Keep body parts and equipment away

from area under and beside the cutter.

• Dangerous projectiles could occur at any

time during cutting. Always wear face and eye

protection. Keep persons away from cutting area.

• Cutter surfaces can become very hot. To prevent

burns, avoid contact with cutter components and

wear appropriate personal protective equipment.

• Refer to additional safety precautions in Section 1.0

of this manual before using the cutter or performing

any maintenance or repair activities.

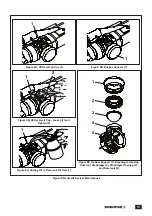

9.3 Trapped Air Removal

Before placing a new cutter into operation, cycle the

piston several times without load to remove any trapped

air in the hydraulic circuit.

Air is completely purged when the piston advances and

retracts smoothly in both directions, from fully advanced

to fully retracted.

This procedure should be performed after the oil in the

cutter is changed, and after any maintenance or repair

activity in which the oil is drained and replaced.

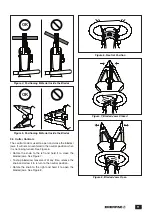

9.4 Positioning Material to be Cut

Position the material to be cut between the cutter blades

so that it is perpendicular to the blade axis, as shown in

Figure 4. This will provide the best quality cut.

Position the material at the base of the blades. Do not

position the material at the tips of the blades. See Figure 5.

NOTICE

Be certain that the properties of the material to

be cut do not exceed the stated maximum limits

applicable to your cutter model. Refer to Section 2.1 of

this manual for additional information. Failure to observe

the instruction may result in poor cutting performance

and/or damage to the cutter.

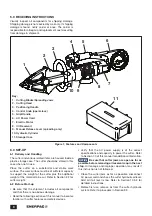

9.0 CUTTER OPERATION

9.1 Foreseen Use and Residual Risks

NOTICE:

WARNING

Failure to observe and comply with the

instructions and precautions contained in the

following paragraphs could result in death or serious

personal injury.

1. The ECSE-Series Cutter/Spreader must be used

only to cut metal tubes, plate, cables and similar

materials during decommissioning or demolition.

The tool may also be used to spread objects apart

for decommissioning, demolition or maintenance

purposes. When cutting, material specifications

must not exceed the allowable values shown in

Section 2.1 of this manual. When spreading, observe

the rated spreading force indicated in Section 2.2, and

the spreading range indicated in Section 2.4 (item D).

2. The tool may be used only if powered by an electrical

system compliant with legislation and current law

(suitably connected to a grounded electrical system

and protected from current surges and short circuits).

3. Operators must observe the instructions in this

manual in order to minimize the risk of accidents. In

particular, operators must pay attention when working

in conditions that could cause:

• Possible burns from overheated metal parts.

• Injury due to incorrect positioning or inadequate lifting

or moving.

• Injury caused by splinters discharged from the

workpiece.

NOTICE:

WARNING

People remaining in the vicinity of the

tool while it is working are subject to the risk of flying

debris (dangerous objects, etc. ). Serious personal

injury could result.

4. Mechanical vibrations transmitted to the hands and

arms can pose a risk to the health and safety of

workers. The user and/or employer is responsible for

assessing the risk generated by mechanical vibrations

from the tool, and minimizing the possibility of injury.

5. Incorrect use:

• The tool must not be used for purposes other than

indicated in this manual.

• The tool must not be used in areas subject to the risk

of explosion.

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...