16

NOTICE

Use only new Enerpac HF oil in the following

step. Use of other oils may damage the cutter and may

invalidate the Enerpac product warranty.

10. Using the oil dispenser prepared in step 1, slowly

add new Enerpac HF oil through the diaphragm

opening until the diaphragm opening is nearly full.

NOTICE:

WARNING

To avoid serious personal injury, stay clear of cutting

head and blades during the following procedures.

Wear rubber gloves to prevent contact with oil. Wear

eye and face protection to avoid injury due to

splashing oil.

11. Connect the cutter to the AC power supply.

12. Cover the diaphragm opening with a rubber-gloved

hand to help prevent oil splashing.

13. Prime the pump by turning the control knob to the

right (open) in short bursts. During this process,

check the oil level in the diaphragm opening and

add oil (as needed) to keep the reservoir filled.

Failure to keep reservoir full may result in cavitation

and pump failure. Pump is primed when jaws start

to open.

NOTICE

During priming, the oil may become entrained

with air and may develop a foamy appearance. This is

normal.

14. Continue turning the control knob to the right (open)

in short bursts until the jaws fully open. During this

process, continue adding oil to keep the reservoir

full.

15. Slowly install the diaphragm in the diaphragm

opening. This should result in some oil leakage from

around the diaphragm.

16. Install and securely tighten the diaphragm cover.

17. Install the rubber support onto the diaphragm

cover.

NOTICE:

WARNING

To avoid serious personal injury, stay clear of cutting

head and blades during the following procedures.

18. Start the cutter and cycle the jaws through several

open and close cycles. Ensure that jaws are fully

closed when done.

19. Disconnect the cutter from the AC power supply.

20. Be sure cutter is positioned so that the oil reservoir

cap is facing upwards. Do not operate cutter for

several hours (preferably overnight) to allow any

remaining air to separate from the oil.

21. Loosen and remove the oil reservoir cap. Recheck

the oil level in the oil drain/fill hole. If oil level has

dropped, add additional Enerpac HF oil until the oil

level is up to the top of the hole.

22. Install and securely tighten the oil reservoir cap.

23. Using a clean rag, wipe the cutter housing, grip and

motor so that surfaces are free of oil residue.

24. Connect the cutter to the AC power supply. Cycle

the piston several times to test for proper operation

before placing the cutter back into service.

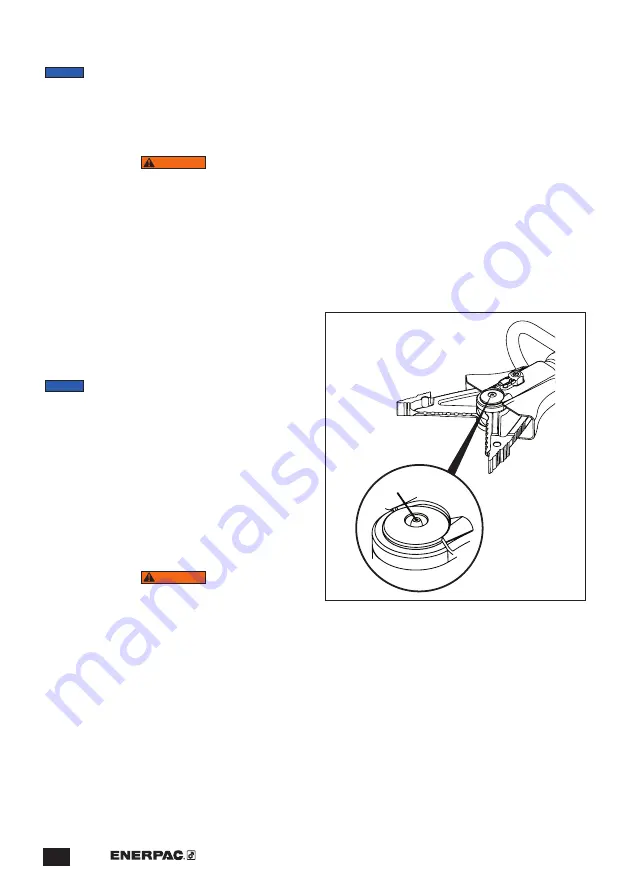

10.6 Greasing the Central Pin

Check that the central pin is lubricated periodically or

daily if used frequently.

To grease the pin, use a lithium-based water repellent

grease. Apply several pumps from a hand grease gun

until grease is evident around the pin. Wipe up any

excess grease. See Figure 10.

1

Figure 10, Grease Fitting, Central Pin (1)

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...