4

1.4.3 Grounding Instructions

DANGER

Risk of electric shock! Connect the tool

only to a properly grounded outlet.

The tool is double insulated and equipped with a

polarized power plug.

The plug must be plugged into a polarized electrical

outlet that is properly installed and wired in accordance

with all local codes and ordinances.

• If the cord and/or plug are damaged, do not connect

the tool to a live electrical outlet. Repair or replace

the damaged items and be sure the polarized plug

is correctly wired before reconnecting the tool to

the outlet. Consult a qualified electrician if wiring

procedures are not completely understood or if there

is any doubt as to whether the tool is properly wired.

• Do not modify the plug provided with the tool.

If the plug will not fit in the outlet, have a proper

outlet installed by a qualified electrician. A qualified

electrician should be consulted if there is any doubt

as to whether an outlet box is properly wired.

• All 230V tool models: The tool is for use on a single-

phase circuit, which has a nominal rating of more

than 120 volts and is factory equipped with a specific

electric cord and plug.

• If the tool must be used with a different type of

electric socket, the plug should be changed by

a qualified electrician. After the plug is changed,

the tool should comply with all local codes and

ordinances.

1.4.4 Use of Extension Cords

It is important to use the proper size extension cord with

the tool power cord when use of an extension cord is

necessary.

A qualified electrician should be consulted to help

specify and select the proper size extension cord.

DANGER

Risk of electric shock! Connect the tool

only to a properly wired outlet.

If an extension cord is used:

1) The marked electrical rating of the extension cord

should be at least as great as the electrical rating of the

tool.

2) The extension cord should have a polarized plug

at one end and a polarized receptacle at the other. It

should be wired for single phase power.

3) A long extension cord should be arranged so that it

will not drape over any working area where it can be

tripped over, snagged, or pulled on unintentionally.

If the tool is to be operated outdoors and an extension

cord is needed, use only an outdoor-use extension cord.

An outdoor-use extension cord will be clearly marked

with the suffix letter “W” and the statement “Suitable for

Use with Outdoor Appliances.”

1.4.5 Additional Precautions

NOTICE:

WARNING

Do not use electric powered tools in an

explosive atmosphere. Sparks and electrical arcing

could ignite combustible vapors or airborne dust.

NOTICE

To prevent damage to the tool electric motor,

check power specifications on tool data plate. Use of

incorrect outlet will damage the motor.

1.5 Safety Symbols (located on cutter)

WARNING

Failure to observe and comply with the

safety symbols affixed to the cutter housing could

result in death or serious personal injury.

WARNING

Make sure the safety symbols (decals,

labels, etc.) are securely affixed to the tool and that

they are legible. If not, obtain replacements from

Enerpac. Refer to tool repair parts sheet for locations

and part numbers. Failure to maintain safety symbols

on tool could result in death or serious personal

injury.

The following safety symbols are affixed to the cutter

housing:

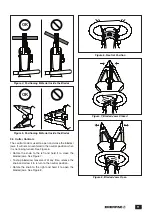

Crush hazard:

Keep hands, fingers and other

body parts away from the cutting head during

operation.

Projectile hazard:

Objects may be ejected

from the cutter during operation. Stay clear of

cutting area. Wear eye and face protection.

PPE Alert:

Wear personal

protective equipment

(PPE) when using or

servicing equipment.

Instruction Manual Alert:

Read the

instruction manual before using or servicing

equipment.

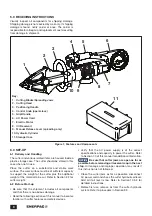

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...