7

2.4 External Dimensions

Dimension

in

mm

A

C

B

D

E

A

23.6

600

B

6.0

154

C

9.3

235

D

11.8

302

E

0.6

16

3.0 CONFORMANCE TO NATIONAL AND

INTERNATIONAL STANDARDS

Enerpac declares that this product has been

tested and conforms to applicable standards

and is compatible with all CE requirements.

A copy of an EU Declaration of Conformity is

enclosed with each shipment of this product.

Product specifications are subject to change without notice.

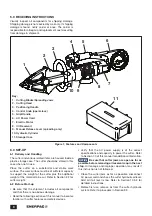

4.0 DESCRIPTION

The Enerpac model ECSE300 is a rotatable head

hydraulic cutter/spreader used for cutting metal

tubes, plate, cables and other similar materials during

decommissioning or demolition activities.

The cutting head can be rotated 180 degrees to access

tight areas. Jaw tips can be inserted between two

objects so that they can be spread apart.

Hydraulic force is provided by an AC-powered electric

motor and an internal hydraulic pump. The pump

provides oil flow to a double-acting hydraulic cylinder,

which opens and closes the cutter jaws.

A hydraulic reservoir with built-in rubber diaphragm

provides a constant supply of oil to the pump, regardless

of tool orientation or the amount of piston extension.

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...