9

7.0 POWER REQUIREMENTS

The cutter is available in two versions, each with different

electrical power requirements:

Model ECSE300B is designed for 120VAC, single-

phase, 60 Hz power. This version contains a USA style

NEMA 6-15 power plug.

Model ECSE300E is designed for 230VAC, single-phase

50 Hz power. This version contains a European style

“Schuko” power plug.

Before connecting electric power to tool, be certain that

the power supply is the proper voltage and Hz for the

cutter version that you are using. Refer to the cutter data

plate.

Also refer to Sections 1.3 and 1.4 of this manual for

important electrical safety information and precautions.

NOTICE:

WARNING

Failure to follow the electrical safety

precautions contained in Sections 1.3 and 1.4 of this

manual could result in electric shock. Death or

serious personal injury could occur.

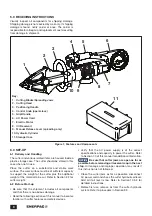

8.0 MAJOR FEATURES AND COMPONENTS

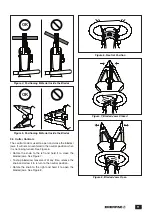

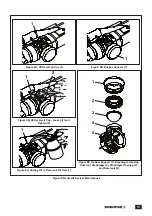

8.1 Rotatable Cutting Head

NOTICE:

WARNING

If the tool is connected to an AC power

supply, the blades can still be closed, even when

manual release lever is set to the unlocked position.

Do not place hands, fingers or other parts of your

body inside the cutting head unless the cutter is

disconnected from the AC power supply. Failure to

follow these instructions and precautions could

result in death or serious personal injury.

NOTICE:

WARNING

Turning the manual release lever to the

unlocked position when spreading will allow the

jaws to depressurize, allowing objects being spread

to potentially become destabilized or return to their

original position. Death, serious personal injury, or

damage to equipment could result.

NOTICE:

WARNING

Always disconnect the cutter from the

AC power supply before rotating the cutting head.

CAUTION

To prevent possible oil leakage, do not

loosen the manual release lever more than one half

turn counter-clockwise.

NOTICE

The cutting head can be rotated only when

the tool is not pressurized. When the manual release

lever is in the unlocked position, the tool will

depressurize, allowing the head to rotate. When in a

depressurized state, the jaws can be closed, but

cannot be opened.

NOTICE

Operate cutter only when the manual

release lever is in the locked position. Jaws will not

open when the manual release lever is in the

unlocked position.

Be sure that the cutter is disconnected from the AC

power supply. Turn the manual release lever counter-

clockwise to position 2 (down) to release the cutting

head.

Using the positioning handle, rotate the cutting head to

the desired position.

Return the manual release lever to the locked position.

See Figures 2 and 3.

NOTICE

The head can still be rotated with the

manual release lever in the locked position if the tool

is not under load. The head locks when the manual

release lever is in the locked position and the tool is

under load.

1

2

Figure 2, Manual Release Lever

Key:

1. Position 1 (locked)

2. Position 2 (unlocked)

Figure 3, Rotatable Cutting Head

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...