12

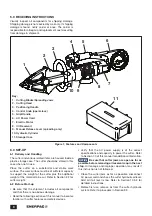

9.6 Cutting Procedure (typical)

1. Be certain that the properties of the material to be cut

do not exceed the stated maximum limits applicable

to your cutter model. Refer to the chart in Section 2.1

of this manual.

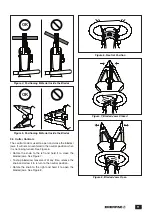

2. Place the material to be cut between the blades.

Be sure that it is perpendicular to the blade axis, as

shown in Figure 4. Refer to instructions in Section 9.4

for additional information.

NOTICE

Failure to properly position the material in

the blades may result in blade breakage and reduced

cutting efficiency.

3. Connect the cutter to the electrical outlet.

4. Turn the control knob to the left and hold it until the

item has been fully cut.

5. Turn the control knob to the right and release it to fully

open the blades. The control knob will return to the

neutral position.

9.7 Spreading Procedure (typical)

1. Turn the control knob to the left to close the jaws.

2. Place the jaws into the area between the two

objects that are to be spread apart. Make sure the

flat spreading wedges on the tips of the jaws are

fully engaged with the objects to be spread, and

properly positioned so they cannot slip out during the

spreading process.

NOTICE:

WARNING

Never place fingers, hands or other

body parts between objects being spread (such as a

joint) during the spreading process.

NOTICE:

WARNING

After spreading is complete, material

may fall. Keep body parts and equipment away from

area under and beside the cutter.

3. Turn the control knob to the right to open the jaws and

begin spreading.

4. Once the spreading is complete, turn the control knob

to the left to close the jaws.

5. Remove the cutter from the objects being spread.

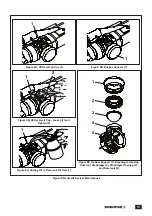

10.0 MAINTENANCE

10.1 Preparation for Maintenance

All cutter maintenance procedures must be performed

under the following conditions:

• Material must be removed from the cutting head.

• The cutter must be disconnected from the AC power

supply.

• The cutter must be given time to cool to prevent burns.

• Procedures must be performed in a suitable work

environment in accordance with all current safety

regulations and/or laws in your country or region.

• The cutter must be cleaned thoroughly before

maintenance procedures are performed.

• Suitable personal protective equipment (PPE) must be

used and/or worn while performing any work.

NOTICE:

WARNING

The cutter must sometimes be

operated in order to complete a maintenance or

repair procedure being performed, or to prepare it

for a procedure that is about to be performed.

However, to prevent start-up while persons are

working on the cutter, always disconnect the cutter

from the AC power supply before beginning any

procedure steps that require use of tools and/or

physical contact with the cutter. Failure to observe

this precaution may result in death or serious

personal injury.

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...