8

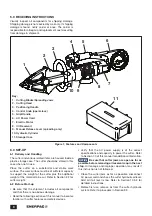

5.0 RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If shipping

damage is found, notify carrier at once. The carrier is

responsible for all repair and replacement costs resulting

from damage in shipment.

1

2

3

4

5

7

8

9

10

6

11

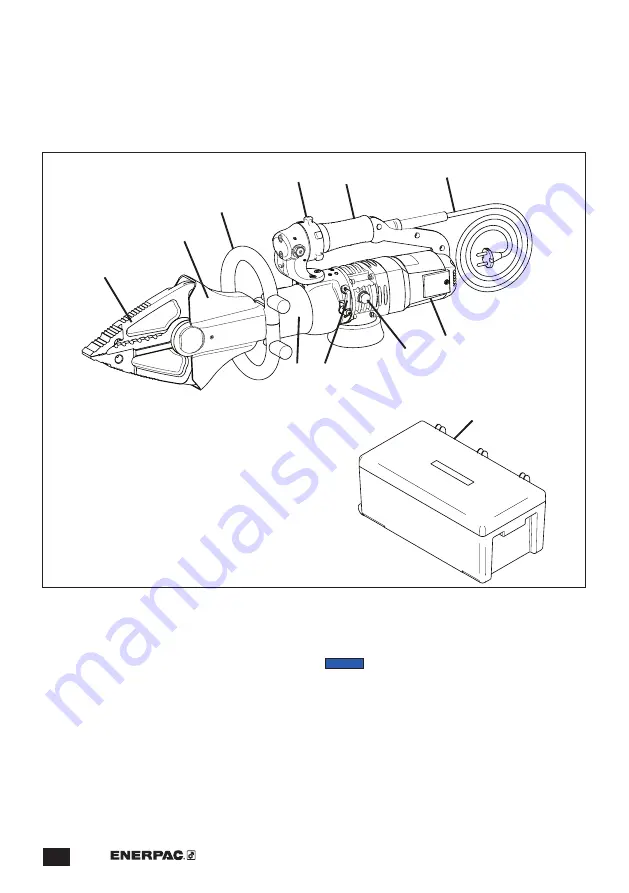

Figure 1, Features and Components

Key:

1. Cutting Blades/Spreading Jaws

2. Cutting Head

3. Positioning Handle

4. Control Knob (open/close)

5. Grip/Handle

6. AC Power Cord

7. Electric Motor

8. Oil Reservoir

9. Manual Release Lever (spreading only)

10. Hydraulic Cylinder

11. Storage Case

6.0 SET-UP

6.1 Delivery and Handling

The cutter and various related items are housed inside a

plastic storage case. The cutter should be stored in this

case when not in use.

Place the cutter on a substantial and stable work

surface. The work surface must be of sufficient capacity

to support the weight of the cutter plus the additional

weight of the material to be cut. Refer to Section 2.2 for

cutter weight.

6.2 Before Start-up

• Be sure that the shipment includes all components

and that there is no obvious damage.

• Read the following sections of this manual to become

familiar with cutter features and safety devices.

• Verify that the AC power supply is of the correct

specifications and capacity to power the cutter. Refer

to Section 7.0 of this manual for additional information.

NOTICE

Be sure that cutter jaws are open as far as

possible before removing oil reservoir cap in the next

step.

Oil leakage and improper operation may result if

this instruction is not followed.

• Close the cutter jaws as far as possible, disconnect

AC power cord and check the cutter hydraulic oil level.

Add oil if oil level is low. Refer to Section 10.5.2 for

detailed instructions.

• Before first use, remove air from the cutter hydraulic

system. Refer to procedure in Section 9.3.

Summary of Contents for ECSE300

Page 20: ...WWW ENERPAC COM...