13

4. To prevent contamination, remove any built-up dust

and dirt from the oil reservoir cap and surrounding area.

NOTICE

A small amount of hydraulic oil may leak from

the drain/fill hole when cap is loosened in the next step.

Be prepared to catch this oil in a pan or with a clean rag.

Dispose of spilled oil in accordance with all applicable

laws and regulations.

5. Slowly loosen the oil reservoir cap while watching for

oil flow:

• If oil starts flowing from the oil drain/fill hole as the

cap is loosened, the reservoir is full. Tighten the

cap immediately. To avoid excessive oil spillage,

do not continue loosening the cap if oil flow

occurs. Skip steps 6 through 8 and go on to step 9.

• If no oil flow occurs when the cap is loosened,

fully loosen and remove the cap. Then, check

oil level and add oil (if needed) as described in

steps 6 through 8.

6. Check the oil level in the drain/fill hole. Oil level will be

up to the top of the hole when reservoir is full.

7. If oil level is low, slowly add new Enerpac HF oil

through the oil drain/fill hole, until the oil level is up to

the top of the hole.

8. Remove any residue or metal particles from the oil

reservoir cap (it is magnetic).

9. Install and securely tighten the oil reservoir cap.

10. Using a clean rag, wipe the cutter housing, grip and

motor so that these surfaces are free of oil residue.

11. Connect cutter to AC power supply. Cycle the

piston several times to test for proper operation

before placing the cutter back into service.

10.5.3 Changing the Oil

NOTICE

The oil change procedure is very detailed and

will take a considerable amount of time. It should only

be performed by a trained technician at an Enerpac

authorized service center. Failure to properly perform

the procedure may result in incomplete filling of the

cutter oil reservoir, which could lead to cavitation, air

entrainment, reduced performance, and pump damage.

Change the oil in the cutter reservoir as described in the

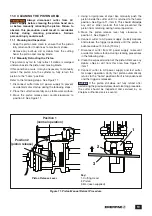

following steps. Refer to Figures 8A through 8E:

1. Fill a clean oil dispenser with new Enerpac HF oil. Put

the dispenser aside for later use.

2. Procure a thick, soft metal bar (about 1/4 inch

[6.4 mm] minimum thickness). Put the bar aside for

later use.

NOTICE

The bar selected should be easy to cut, but not

brittle. The bar material must be soft enough so that the

bar will not break into two pieces before it is fully cut.

Later in this procedure, the bar will be partially cut so

that it becomes lodged in between the jaws of the cutter

without being cut through completely, as the piston is

extended to slightly less than maximum travel.

10.5.1 Hydraulic System Maintenance Precautions

NOTICE:

WARNING

Always disconnect cutter from AC power supply

before performing hydraulic system maintenance.

Failure to observe this precaution could result in

accidental startup while maintenance procedures

are being performed. Serious personal injury and

damage to cutter may result.

Wait for cutter to cool before performing hydraulic

system maintenance. Hot oil can cause burns.

Be sure that oil reservoir cap is securely tightened

after checking oil level or changing the oil. Leaking

oil can cause short circuits, fire and explosions.

Additional Precautions:

• Do not check oil level or change the oil in dusty areas.

• Be sure that all tools (wrench, screwdriver, etc.) used

to perform maintenance procedures are clean.

• When adding oil and performing oil changes, take every

precaution to prevent impurities from contaminating

the oil or entering the cutter. Impurities can cause

permanent damage to the hydraulic components.

• The hydraulic reservoir contains a rubber diaphragm

that slightly pressurizes the oil. Some oil spillage may

occur when checking the oil level or when changing

the oil. Wear and/or use appropriate personal

protective equipment (PPE) to prevent exposure to

hydraulic oil.

• Use only new Enerpac HF hydraulic oil poured from a

clean container. Use of other oil brands and/or used

oil may damage the cutter and may void the Enerpac

product warranty.

10.5.2 Checking Oil Level and Adding Oil

NOTICE

The reservoir contains a flexible rubber

diaphragm that slightly pressurizes the oil. To help prevent

excessive oil leakage when the reservoir cap is removed,

be certain that the piston is advanced until there is a gap

of about 1/8 inch [3-4 mm] between the fixed and moving

blades (as described in step 1) before loosening the cap.

The gap between the blades should not be less than

1/8 inch [3-4 mm]. A smaller gap may result in the

piston retracting unexpectedly while the oil level is being

checked.

Refer to Figures 8A through 8E during the following steps:

1. Operate the cutter and advance the piston until

there is a 1/8-inch [3-4 mm] gap between the fixed

and moving blades (until just before the piston

automatically returns).

2. Disconnect the cutter from the AC power supply to

prevent accidental motor startup during the following

steps.

3. Place the cutter in the horizontal position, on a stable

and level work surface, with the oil reservoir cap

facing upwards. Place a pan or suitable container

under the cutter to catch any spilled oil.

Summary of Contents for EFBE5017

Page 23: ...Notes...

Page 24: ...WWW ENERPAC COM...