15

3. Disconnect the cutter from the AC power supply to

prevent accidental motor start-up during the following

steps.

4. Place the cutter in an upright position, on a stable and

level work surface, with the handle facing upwards.

Place a pan or suitable container under the cutter to

catch any spilled oil.

5. To prevent contamination, remove any built-up dust

and dirt from the oil reservoir cap, diaphragm cover,

and surrounding area.

NOTICE

When the handle is removed the wires from the

trigger on-off switch will still be connected to the electric

motor. Take care not to pull or stretch the wires when

removing the handle or when performing the oil change

procedure.

6. Remove the screws holding the tool handle in place.

Carefully remove the tool handle to gain access to the

diaphragm cover. The tool handle wiring will still be

connected, so use caution to avoid damaging this

wiring.

NOTICE

A small amount of hydraulic oil leakage may

occur when the diaphragm cover is removed in the next

step. Be prepared to catch this oil in a pan or with a

clean rag. Dispose of spilled oil in accordance with all

applicable laws and regulations.

7. Remove the diaphragm cover by removing the six

screws securing it.

8. Remove the diaphragm from the diaphragm opening.

9. Completely drain all old oil from the cutter through the

diaphragm opening, turning it upside down and using

a suitable oil extraction system (used oil extraction

pump) if necessary, so that no oil remains in the cutter

reservoir.

NOTICE

Dispose of all used oil in accordance with all

applicable regulations and laws.

10. After all oil is evacuated, position the cutter with the

diaphragm opening facing up.

NOTICE

Use only new Enerpac HF oil in the following

step. Use of other oils may damage the cutter and may

invalidate the Enerpac product warranty.

11. Using the oil dispenser prepared in step 1, slowly

add new Enerpac HF oil through the diaphragm

opening until the diaphragm opening is nearly full.

NOTICE:

WARNING

To avoid serious personal injury, stay

clear of cutting head and blades during the following

procedures. Wear rubber gloves to prevent contact

with oil. Wear eye and face protection to avoid injury

due to splashing oil.

NOTICE:

WARNING

In the following steps, the tool must be

operated with the handle separated from the tool

housing. Use extreme caution to prevent injury as

service procedures are being performed.

12. Connect the cutter to the AC power supply.

13. Cover the diaphragm opening with a rubber-gloved

hand to help prevent oil splashing.

14. Prime the pump by pressing and releasing the

trigger in short bursts. During this process, check

the oil level in the diaphragm opening and add oil

(as needed) to keep the reservoir filled. Failure to

keep reservoir full may result in cavitation and

pump failure. Pump is primed when piston starts

extending.

NOTICE

During priming, the oil may become entrained

with air and may develop a foamy appearance. This is

normal.

15. Continue pressing and releasing the trigger in short

bursts as the piston extends. During this part of the

process, do not add oil, but verify that the pump has

ample oil supply. Continue until piston is extended

to approximately half stroke.

NOTICE

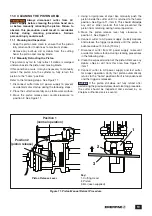

During the following steps, refer to Figure 5 for

piston release lever positions.

16. While covering the diaphragm opening with a

rubber-gloved hand, retract the piston gently by

slowly moving the piston release lever to position 2.

17. Move the piston release lever back to position 1 and

tighten.

18. Place the soft metal bar (refer to step 2) into the

cutting head.

19. Press and release the trigger in short bursts until

the piston is extended as far as possible, but before

it makes a full cut and retracts. The moving blade

will become lodged in the bar, preventing the

piston from retracting. This procedure is necessary

because the cutter mechanism alone may fail to

hold the piston in the partially extended position as

oil is being added in the following steps.

NOTICE

If you cut completely through the bar, try again,

cutting as far as you can without making a full cut.

20. Disconnect the cutter from the AC power supply

to prevent accidental motor start-up during the

following steps.

21. Add oil through the diaphragm opening until the

diaphragm opening is nearly full.

22. Slowly install the diaphragm in the diaphragm

opening. This should result in some oil leakage from

around the diaphragm.

23. Install the diaphragm cover and securely tighten the

six screws securing it.

24. Reinstall the tool handle. Be certain that electrical

wires are not pinched between tool housing and

handle.

25. Move the piston release lever to position 2 to retract

the piston. If piston is stuck, use the bar to manually

push the piston back until it retracts.

26. Remove the soft metal bar from the cutting head.

Do not discard the bar. It will be used again later in

this procedure.

Summary of Contents for EFBE5017

Page 23: ...Notes...

Page 24: ...WWW ENERPAC COM...