8

8.0 MAJOR FEATURES AND COMPONENTS

8.1 Trigger On-Off Switch

NOTICE:

WARNING

To prevent serious personal injury, be

certain that hands, fingers and other body parts are

away from the cutting area before depressing the

cutter trigger.

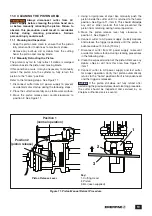

A trigger mounted in the cutter grip controls cutter

operation. Pressing the trigger automatically starts the

cutter electric motor.

• Press and hold the trigger to advance the piston and

slide the moving blade forward. See Figures 2 and 3.

• Release the trigger at any time to stop the piston and

moving blade. Be advised that there may be a brief

delay until the piston comes to a complete stop.

• After the piston is fully advanced the piston will

automatically reverse direction and move to the fully

retracted “home” position. See Figure 4.

• Automatic return can occur only after the piston has

been fully advanced. If the trigger is released before

the piston is fully advanced, the piston will stop and

remain stopped.

Figure 2, Trigger On-Off Switch

Figure 3, Piston and Blade Fully Advanced

6.0 SET-UP

6.1 Delivery and Handling

The cutter and various related items are housed inside a

plastic storage case. The cutter should be stored in this

case when not in use.

Place the cutter on a substantial and stable work

surface. The work surface must be of sufficient capacity

to support the weight of the cutter plus the additional

weight of the material to be cut. Refer to Section 2.2 for

cutter weight.

6.2 Before Startup

• Be sure that the shipment includes all components

and that there is no obvious damage.

• Read the following sections of this manual to become

familiar with cutter features and safety devices.

• Verify that the AC power supply is of the correct

specifications and capacity to power the cutter. Refer

to Section 7.0 of this manual for additional information.

NOTICE

Be sure that cutter piston is advanced as far

as possible before removing oil reservoir cap in the

next step.

Oil leakage and improper operation may

result if this instruction is not followed.

• Advance the piston as far as possible, disconnect AC

power cord and check the cutter hydraulic oil level.

Add oil if oil level is low. Refer to Section 10.5.2 for

detailed instructions.

• Be sure that the piston release lever is fully tightened.

Refer to Section 8.2.

• Before first use, remove air from the cutter hydraulic

system. Refer to procedure in Section 9.3.

7.0 POWER REQUIREMENTS

The cutter is available in two versions, each with different

electrical power requirements:

Model EFBE5017B is designed for 120VAC, single-

phase, 60 Hz power. This version contains a USA style

NEMA 6-15 power plug.

Model EFBE5017E is designed for 230VAC, single-

phase 50 Hz power. This version contains a European

style “Schuko” power plug.

Before connecting electric power to tool, be certain that

the power supply is the proper voltage and Hz for the

cutter version that you are using. Refer to the cutter data

plate.

Also refer to Sections 1.3 and 1.4 of this manual for

important electrical safety information and precautions.

NOTICE:

WARNING

Failure to follow the electrical safety

precautions contained in Sections 1.3 and 1.4 of this

manual could result in electric shock. Death or

serious personal injury could occur.

Summary of Contents for EFBE5017

Page 23: ...Notes...

Page 24: ...WWW ENERPAC COM...