24

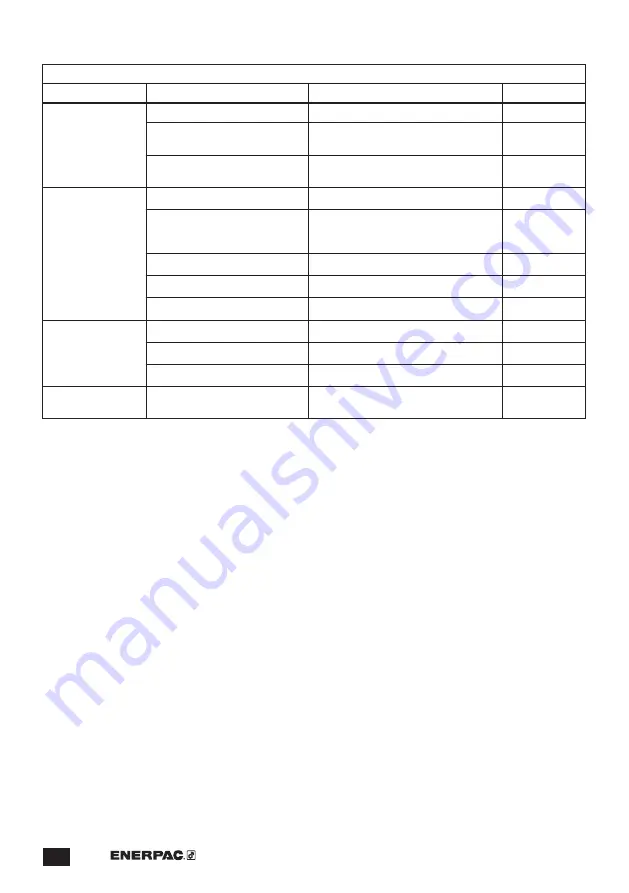

Table 3 - Troubleshooting Chart, Cutter Hydraulic Components

Symptom

Possible Cause

Solution

Maint. Level

1. Piston does not

advance.

Low hydraulic oil level.

Check oil level. Add oil if low.

Operator

Directional lever not set to

advance position.

Move lever to advance position.

Operator

Max. pressure valve dirty or

requires replacement.

Clean or replace max. pressure valve.

Service Center

2. Piston does

not fully

advance and/or

movement is

jerky.

Low hydraulic oil level.

Check oil level. Add oil if low.

Operator

Air bubbles in the hydraulic

circuit.

Operate tool through several full cycles

to bleed air. Check oil level and add

oil if low.

Operator

Max. pressure valve open.

Clean or replace max. pressure valve.

Service Center

Piston gasket worn.

Replace piston gasket.

Service Center

Pump malfunction.

Repair or replace pump.

Service Center

3. Tool performs

with insufficient

force.

Max. pressure valve open.

Replace pressure valve.

Service Center

Piston gasket worn.

Replace piston gasket.

Service Center

Pump malfunction.

Repair or replace pump.

Service Center

4. Oil leakage from

oil reservoir.

Reservoir diaphragm faulty.

Replace reservoir diaphragm.

Service Center

(Refer to Table 2 for electrical component troubleshooting.)