13

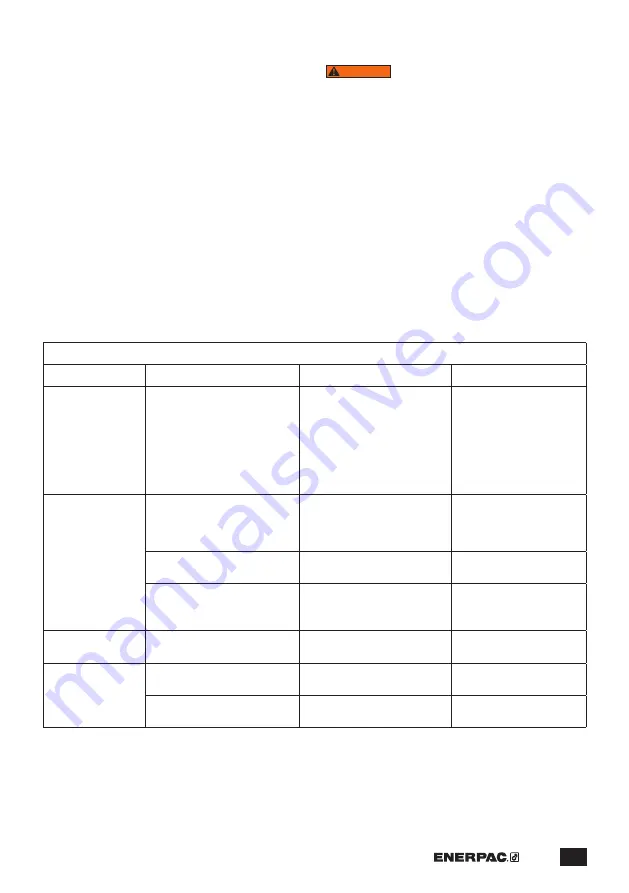

Table 1 - Periodic Maintenance Chart

Time Interval

Maintenance Operation

Method

To be performed by:

Frequently during

use:

Check for any cutting

remnants or debris that have

collected in the cutting head.

If these items are found,

disconnect the cutter from

the AC power supply and

remove remnants or debris as

required.

Visual (refer to instructions in

Section 10.3)

Operator

Every 8 hours of

operation:

Check the cutter for loose,

damaged or worn parts.

Check for oil leaks. Tighten,

replace or repair as required.

Visual

Operator

Clean the cutter exterior.

Refer to instructions in

Section 10.3

Operator

Check the tightening torque

of screws and bolts. Replace

any missing screws or bolts.

Use torque wrench. Refer to

repair parts sheet for complete

torque specifications

Operator

Every 1600 hours

of operation:

Change the hydraulic oil.

Refer to instructions in

sections 10.5.1 - 10.5.3

Service Center

As required:

Replace fixed blade.

Refer to instructions in

Section 10.6.2

Operator

Replace moving blade.

Refer to instructions in

Section 10.6.3

Operator

NOTICE:

WARNING

The cutter must sometimes be

operated in order to complete a maintenance or

repair procedure being performed, or to prepare it

for a procedure that is about to be performed.

However, to prevent start-up while persons are

working on the cutter, always disconnect the cutter

from the AC power supply before beginning any

procedure steps that require use of tools and/or

physical contact with the cutter. Failure to observe

this precaution may result in death or serious

personal injury.

10.2 Periodic Maintenance Chart

Refer to the Periodic Maintenance Chart (Table 1) for a

list of various routine checks and procedures.

10.0 MAINTENANCE

10.1 Preparation for Maintenance

All cutter maintenance procedures must be performed

under the following conditions:

• Material must be removed from the cutting head.

• The cutter must be disconnected from the AC power

supply.

• The cutter must be given time to cool to prevent burns.

• Procedures must be performed in a suitable work

environment in accordance with all current safety

regulations and/or laws in your country or region.

• The cutter must be cleaned thoroughly before

maintenance procedures are performed.

• Suitable personal protective equipment (PPE) must be

used and/or worn while performing any work.