20

L4478_a

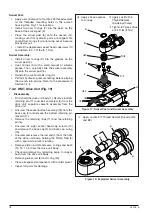

7.3.3 HMT HLP Cassette Assembly -

Disassemblyand Reassembly (Fig. 20/ 21)

• With the HLP cassette laid down on it side, remove

the three front spacer screws (12) and two reaction

block screws (13) followed by the one of HLP

cassette side plate (1 or 2).

• Separate the ratchet bush (14). The drive plate

assembly is free to be removed from the cassette.

Carefully remove the two compression springs (8)

from the drive plate and set to one side.

• Remove the ratchet (4), pawl (5) and pawl springs

(6).

• Disengage the two drive pin retainers (9), and slide

out the drive pin (7) from the drive plate

(3)

.

• On the remaining plate remove the three front

spacer screws (12) and two reaction block screws

(13) separate front spacer (11) and reaction block

(10) from the remaining HLP cassette side plate (1

or 2).

• Disassemble the reaction block by removing the

two socket head cap screws (17), and remove the

wear plate (16) from reaction block spacer (10).

• Clean all components with a mild solvent.

• Inspect all parts for damage. Any damaged

components must be replaced.

• Dry all components. Apply a thin coat of

molybdenum disulphide grease in the areas shown

in Figure 20.

Be sure that the ratchet, drive plate,

pawl, pawl spring, square drive, access plugs, and

compression springs are correctly installed, in the

reverse order of disassembly. Failure to install these

parts correctly will result in component damage. Refer

to figures 19 and 20.

• Assemble the HLP cassette assembly to the

appropriate drive unit body.

• Connect the wrench to the pump and perform

hydraulic pressure testing before placing the wrench

into service. Refer to the procedure in Section 7.2.6.

• Without the wrench on a nut or bolt, check

operation at a nominal pressure to make sure the

piston advances and retracts freely.

• Release the pressure and make sure that the piston

fully retracts.

NOTICE

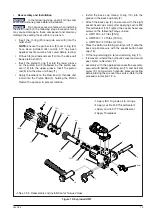

7.3.4 HMT HSQ Cassette Assembly -

Disassemblyand Reassembly (Fig. 22/ 23)

• To separate the square drive reaction arm (4),

unscrew the securing reaction arm grub screw (20)

and disengage.

• Remove the square drive circlip (8) and slide

the reaction arm spline (3) off the square drive

(2). Separate the drive bush (6) and remove the

remaining reaction arm circlip (9).

• Remove the square drive (2), drive retainer ring (21),

retainer block (5), and push button retainer (16).

• Remove the front spacer pins (22) followed by the

front spacer (15).

• The drive plate assembly is free to be removed

from the body. Carefully remove the two rod end

pin spring (18) from the drive plate and set to one

side.

• Disengage the two drive pin retainers (19), and

slide out the rod end pin (10) from the drive plate

(11)

.

• Remove the splined ratchet (7), pawl (

14

) and pawl

springs (13).

• If the linkpin (12) requires replacement, unscrew

the M4 button head screw (24) and separate link

pin and lanyard (23) from the body.

• Clean all components with a mild solvent.

• Inspect all parts for damage. Any damaged

components must be replaced.

Do not apply molybdenum disulphide

grease to the ratchet lever bore, or to the drive shoe

teeth. Application of grease to these areas will cause

erratic operation, slippage of drive mechanism and

excessive component wear.

• Dry all components. Apply a thin coat of

molybdenum disulphide grease in the areas shown

in Figure 22.

Be sure that the ratchet, drive plate,

pawl, pawl spring, square drive, access plugs, and

compression springs are correctly installed, in the

reverse order of disassembly. Ensure that the square

drive is inserted through the drive plate. Failure to install

these parts correctly will result in component damage.

Refer to figures 21 and 22.

• Assemble the Square Drive Cassette assembly to

the appropriate wrench body.

• Connect the wrench to the pump and perform

hydraulic pressure testing before placing the wrench

into service. Refer to the procedure in Section 7.2.6.

• Without the wrench on a nut or bolt, check

operation at a nominal pressure to make sure the

piston advances and retracts freely.

• Release the pressure and make sure that the piston

fully retracts.

NOTICE

NOTICE

Summary of Contents for HMT Series

Page 2: ......

Page 44: ...2020 Enerpac Tool Group All Rights Reserved www enerpac com...