Before a swing cylinder can be manifold mounted, the port screw plugs and

copper gaskets must be removed.

The o-rings provided should be lubricated and installed in the counter-

bore around the port prior to mounting and bolting down the swing

cylinder.

Be sure that the o-ring does not get pinched or damaged during

mounting as leakage could result. To prevent leakage from the

manifold mounting, provide a fixture mounting surface with

flatness within 0,08 mm (0.003 in.) and a surface roughness not

to exceed Ra 1,6.

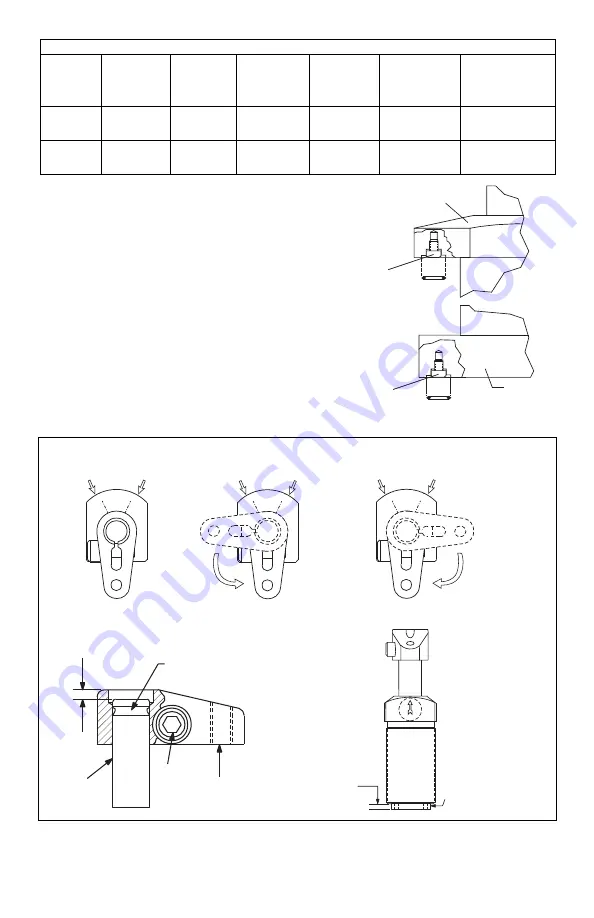

6.0 INSTALLATION

These Swing Cylinders are designed so that you can set the

position of the clamp arm after mounting the cylinder. If you need

to change the rotation direction, do it before mounting the

cylinder.

6.1 Changing Plunger Rotation (if needed)

5

Manifold Specifications

Cylinder Max.

Oil

Fixture

Mounting

Minimum

Lubricated

Manifold

Capacity

Channel

Hole

Threads

Thread

Mounting

O-Ring

Diameter

Diameter

Depth

Bolt Torque

Dimensions

Ø A

Ø B

C

D

I.D. x w

2,2 kN

4 mm

1.15 ± .03

M5

12 mm

4,5-5,4 Nm

6,07 x 1,78 mm

500 lb

0.156"

0.473"

40-48 in-lbs

0.239 x 0.070"

5,6 kN

4 mm

1.42 ± .03

M6

15 mm

12,2-14,9 Nm

7,65 x 1,78 mm

1250 lb

0.156"

0.591"

9-11 ft-lbs

0.301 x 0.070"

A

B

S

L

R

A

B

R

S

L

A

B

L

R

S

.25 "

(6,4mm)

6,4 mm

(0.25")

Clamp position

Unclamp port

Unclamp position

Clamp port

Clamp position

Clamp and

unclamp position

Unclamp

position

Unclamp port

Clamp port

Unclamp port

Clamp port

Retaining ring removed

from groove.

Plunger

Clamp

arm

bolt

Clamping

arm

Approximately

4 turns out.

Bottom plug

STRAIGHT

LEFT SWING

RIGHT SWING

Upper Flange

Remove port

screw plug.

O-ring

O-ring

Lower

Flange

Remove port

screw plug.