2

2

3

4

9

10

5

6,

7

5

8

1

2.1 Hydraulic Nut Splitter Safety Precautions

WARNING:

Failure to observe the following precautions

may result in serious personal injury or death!

• Personal protective equipment must be worn at all times. Use

of safety footwear, thick gloves, overalls and safety glasses

is mandatory. These items are in addition to any other safety

equipment required at your site.

• Keep personnel clear while pressurizing the system. Allow

only relevant personnel to be within the work zone.

• Never exceed the maximum working pressure of the nut

splitter or any associated ancillary equipment. The maximum

working pressure of the nut splitter is 10,000 psi [700 bar].

• Do not place fi ngers or any part of the body between the nut

splitter and the nut. Keep hands clear of the nut splitter head

at all times and especially in the vicinity of the blade.

• Do not place fi ngers or hands underneath the body of the

nut splitter to support the weight, as hands or limbs could be

trapped when the pressure is applied.

• Lift the nut splitter using only the provided lifting eyebolt.

Always use appropriate lifting equipment. See Section 3.1 for

weights.

•

The nut splitter handle is provided for positioning and

maneuvering purposes only. Do not use the handle to carry the

nut splitter.

• Do not strike the nut splitter (or any of its components) with a

hammer or other objects in an attempt to shock or impact the

nut.

• Do not attempt to move or reposition the nut splitter while it

is in operation.

• Do not apply heat to the nut while the nut splitter is positioned

on the nut.

• When in operation, do not stand along the axis of the nut

splitter. Always stand to the side.

• Do not cut the nut into small pieces. Use a maximum of two

cuts. The second cut must always be at 180º (opposite) to the

fi rst.

• Hydraulic couplers are susceptible to knocks and damage.

Therefore, be careful when handling the equipment. A damaged

coupler or fi tting may burst or eject fl uid under pressure.

• Always allow the nut splitter cylinder to fully retract before

disconnecting hydraulic hose(s). High-pressure fl uid may be

ejected from an unretracted cylinder if a coupler has been

damaged during handling.

• Fully release hydraulic pressure and disconnect hydraulic

hose(s) from nut splitter cylinder before applying lubricant to

blade or performing any other work inside the cutting zone.

• Be careful when handling severed nuts. Sharp edges can

cause lacerations.

• Always use the correct size cutting head for the nut to be

cut.

• Do not insert packing pieces or shims behind the nut or

blade in an attempt to split a nut that is not within the specifi ed

size range for the cutting head.

• Use the nut splitter to cut hexagonal nuts only. Do not attempt

to cut square, round, bi-hex or 12-point nuts.

• Do not use the nut splitter to cut chains or bolts.

• Do not use the nut splitter to rotate nuts.

• Do not use the nut splitter's hydraulic cylinder for jacking,

lifting, pushing or any other purpose than that for which it is

intended.

• Sparks can be emitted at the blade tip when the nut fractures.

To minimize the risk of sparks or hot metal fragments, a water

spray can be directed over the entire nut and blade area.

However if there is any doubt as to whether sparks can be

effectively arrested, then the nut splitter should not be used.

• Never attempt to disconnect or retighten any part of the

hydraulic system while under pressure. Be sure pressure

gauge indicates zero (0) psi/bar before attempting to connect,

disconnect or tighten hydraulic fi ttings.

• Treat hydraulic hoses with care. Do not kink, twist or sharply

bend any hydraulic hose. Never exceed the hose manufacturer's

specifi ed minimum bend radius. Never use a damaged, worn

or split hose.

• Read and understand the operating instructions, maintenance

instructions and safety precautions contained in this instruction

sheet.

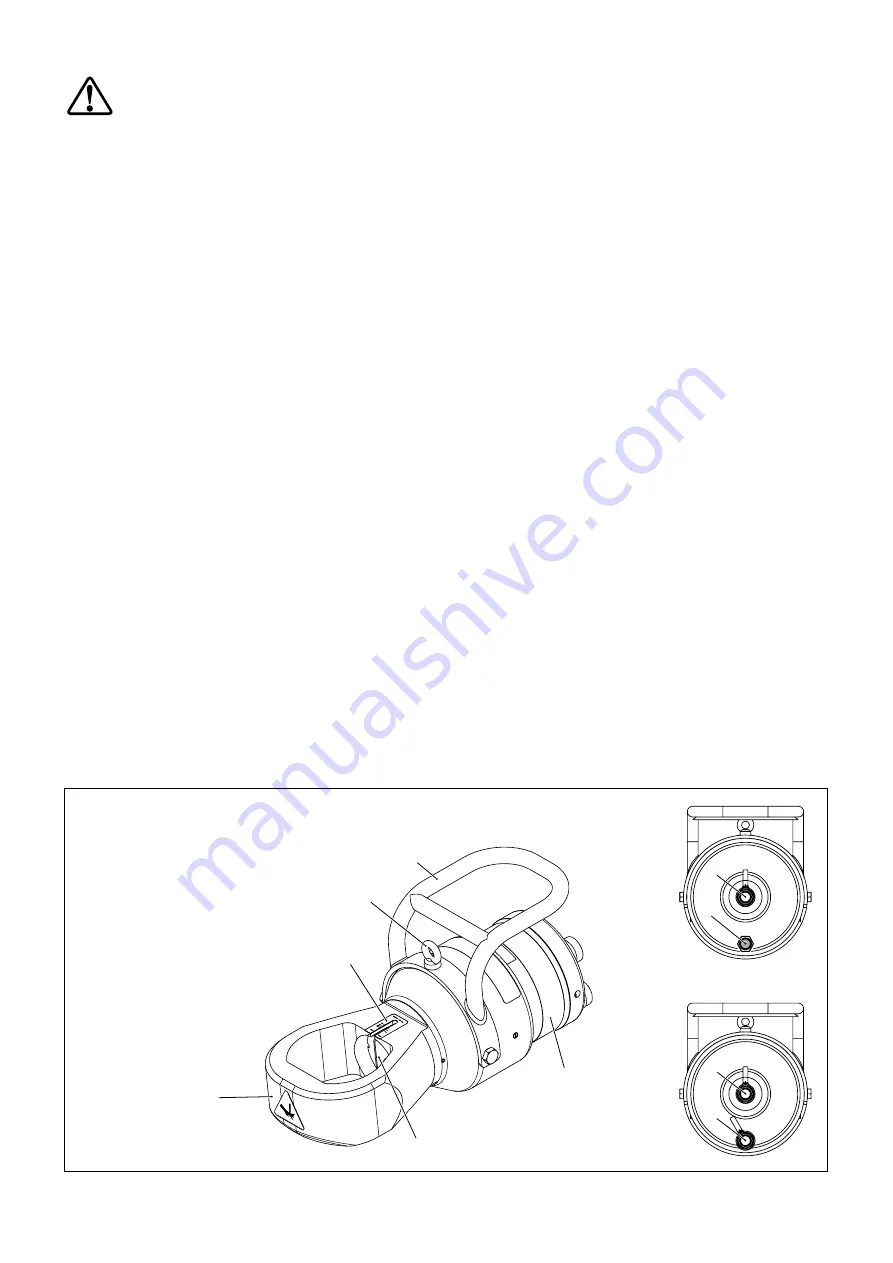

Figure 1, Features and Components, NS Series Nut Splitter

(rear view)

Single

Acting

Models

Double

Acting

Models

1. Cutting Head

2. Blade Cutting Depth Scale

3. Lifting Eyebolt

4. Handle

5. Hydraulic Coupler

6. Vent Plug

(single acting NS70 models only)

7. Pipe Plug

(single acting NS110 models only)

8. Hydraulic Coupler

(double acting models only)

9. Hydraulic Cylinder

10. Cutting Blade