4

5.0 ASSEMBLY

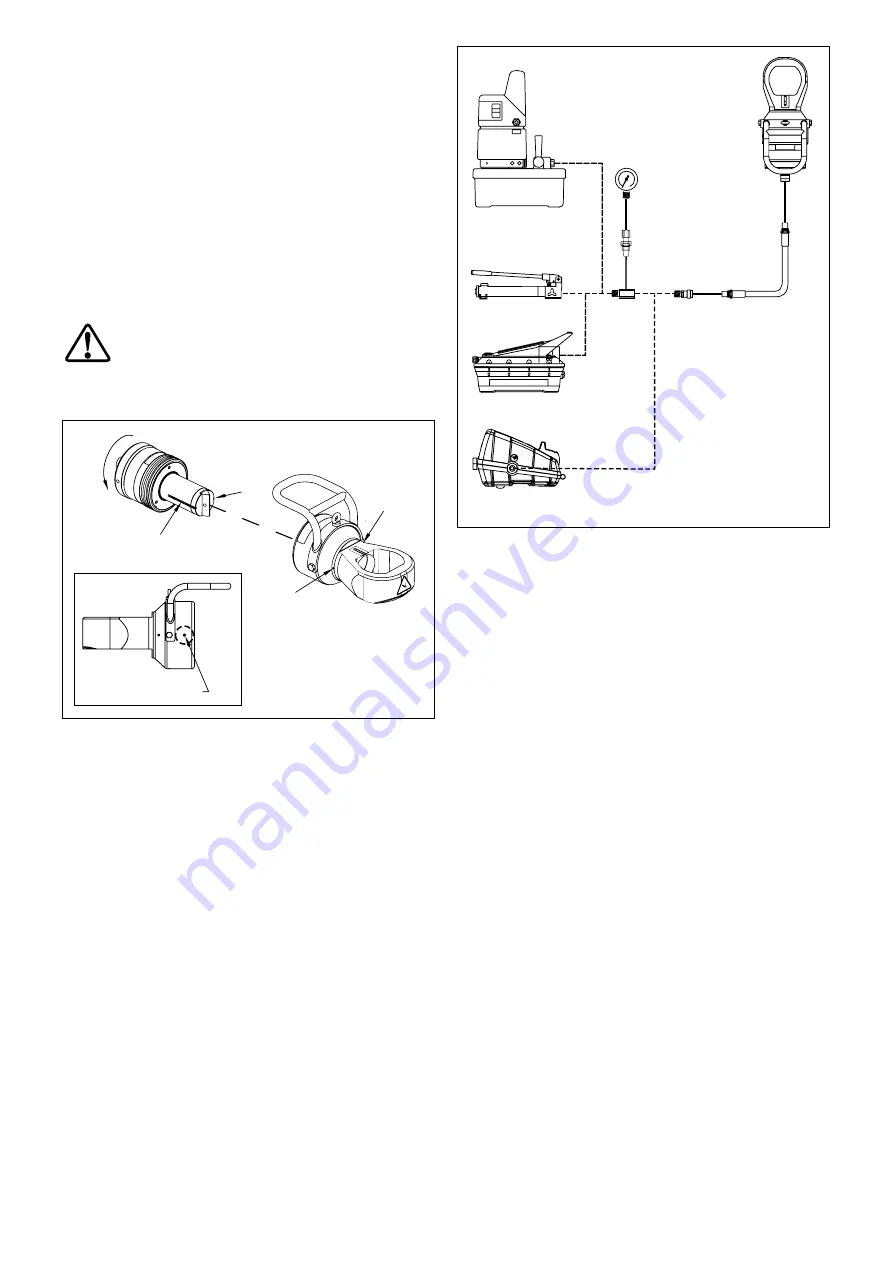

5.1 Assembling Cutting Head and Cylinder

The cutting head is shipped disassembled from the cylinder.

Assemble as described in the following steps:

1. Be sure that cylinder is fully retracted and disconnected

from the hydraulic pump.

2. Loosen the plastic set screw (Figure 3, item A) located on

the cutting head barrel.

3. Insert the cylinder into the head, aligning the axial slots

in the blade holder (Figure 3, item B) with the spring pins

(Figure 3, item C) in the cutting head bore. Once aligned,

rotate the cylinder in the direction shown in order to engage

the screw threads.

4. Continue rotating the cylinder until NO threads are visible on

the outside of the cylinder body (threads fully engaged).

WARNING:

Never use the nut splitter if any of the

cylinder threads are visible.

5. Install the cutting blade. Refer to Section 7.0 for installation

instructions.

B

A - Set Screw

B - Grooves

C - Spring Pins (inside bore)

C

B

C

A

Figure 3, Assembling the Cylinder and Cutting Head

5.2 Hydraulic Pump

A 10,000 psi [700 bar] hydraulic pump is required to operate

the nut splitter.

If a single acting nut splitter is used, the pump must be

equipped with a pressure release valve. If a double acting nut

splitter is used, the pump must be equipped with a suitable

4-way 3-position directional control valve.

Always check the pump hydraulic relief valve setting before

connecting the nut splitter. Maximum pressure must not exceed

10,000 psi [700 bar].

If an air-powered hydraulic pump is used, an air regulator must

be installed in the air supply line, limiting the air pressure to the

recommended range for the pump being used.

If the pump is not equipped with a hydraulic pressure gauge,

install a 0-10,000 psi [0-700 bar] gauge between the pump

outlet and the hydraulic hose.

5.3 Hose Connections

Be sure to use only high pressure hoses and fi ttings designed

for 10,000 psi [700 bar] operation. See Figure 4 for typical

pump and hose arrangements.

Single acting nut splitters are equipped with

one

Enerpac

CR-400 3/8" female coupler. Double acting nut splitters are

equipped with

two

Enerpac CR-400 3/8" female couplers.

Figure 4, Hydraulic Connections (typical pumps shown)

Connect the hydraulic hose(s) between the pump and the nut

splitter cylinder. Check that couplers on both ends of hose(s)

are fully screwed together. Firmly tighten couplers by hand to

prevent restricted oil fl ow.

IMPORTANT:

Be sure that all couplers are fully connected.

Loose or partially connected couplers will block the fl ow of oil

between the pump and the nut splitter.

To remove any air trapped in the system, advance and retract

the cylinder several times.

6.0 OPERATION

6.1 Adjusting Blade Cutting Depth

(If bolt diameter is shown on the scale)

The blade cutting depth scale allows the user to set the nut

splitter's maximum stroke, and the corresponding depth of

the cutting blade. This feature helps prevent bolt damage from

occurring due to excessive blade penetration.

Adjust the cutting depth as described in the following steps:

1. Ensure that the nut splitter cylinder is fully retracted.

2. Check that the bolt diameter is within the range of the

cutting head to be used (bolt diameter range is indicated

on the scale). See Section 3.2 for additional information.

Note:

The cutting depth scale is calibrated only for the following

thread, bolt and nut types:

Imperial threads

- Unifi ed (UN) bolt threads with heavy series

nuts.

Metric threads

- Metric (M) bolt threads with standard series

nuts.

If any other thread, bolt or nut type is present, skip the following

steps in this section and refer to Section 6.2 for additional

instructions.

Enerpac PU Series

Electric Pump

Enerpac P Series

Hand Pump

Enerpac PA Series

Air-Hydraulic Pump

Enerpac XA Series

Hydraulic Pump

0-10,000 psi

[0-700 bar]

Pressure Gauge

Note:

Hose arrangement for

single acting nut splitter

models is shown.

Double acting nut splitter

models require TWO

hoses, one for

extend

and one for

retract

.