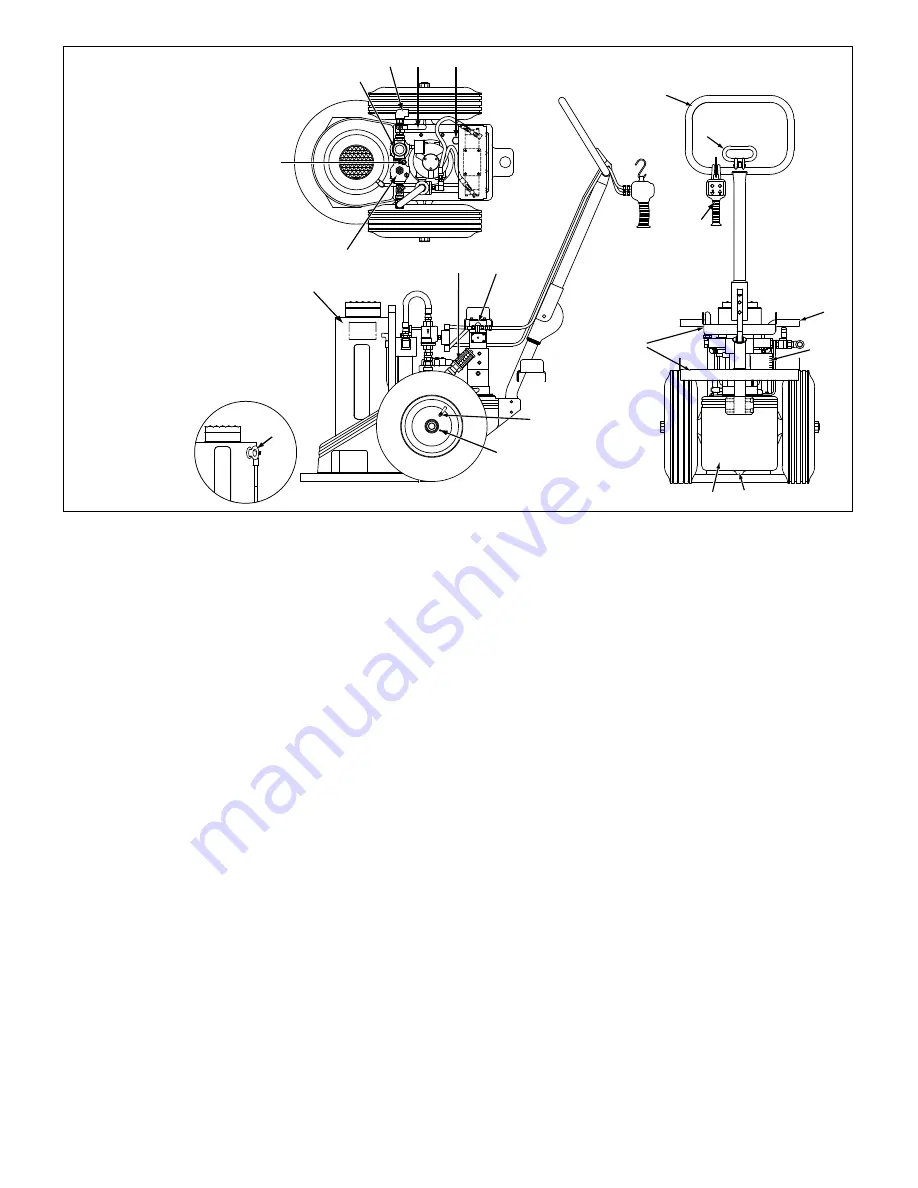

4.0 INITIAL SETUP

4.1 Adding Oil

Before startup, remove the oil fi ll plug (callout #11) and check

oil level. Oil level should be about 1 inch [25 mm] below top of

reservoir. Add Enerpac HF hydraulic oil to reservoir if necessary.

See Section 6.1 for additional information.

4.2 Air Requirements

Lubricated air is necessary to provide shaft seal lubrication for the

air motor, and to prevent rust. All models are equipped with an

automatic air line lubricator set to feed approximately 3 drops per

minute.

Before startup, check the level in the air line lubricator (callout #7)

and add additional lubricant if needed. Use an SAE 10 [ISO 32]

detergent oil or an approved antifreeze lubricant. See Section 6.4

for additional information.

A fi lter/regulator with moisture trap (callout #9) is installed in the

air line ahead of the motor. For effi

ciency of output and control

of speed, use an air line of not less than 3/4 inch pipe size. Air

pressure and fl ow must be at least 50 CFM @ 80 psi

[

1416 l/min

@ 5,5 bar]. The air inlet connection is a 1/2" NPT female thread.

Be certain that compressed air is clean and dry. Moisture in the

air line can cause rust formation in the air motor and may result

in reduced performance. Allowing excessive moisture or foreign

particles to enter the air motor will void the Enerpac warranty.

4.3 Using the Jack for The First Time

Note:

Refer to Section 5.0 for detailed jack operation instructions.

1.

On PRAMA Series models, be sure that the control valve lever

is in the center (neutral/hold) position.

Note:

On PRASA Series models, the air operated control valve

automatically returns to the center (neutral/hold) position when

the pendant buttons are not depressed.

2.

Connect an air hose at the air inlet connection (callout #10).

Note:

On PRAMA Series models, the motor will start immediately

when the air supply valve is opened. On pendant controlled

PRASA Series models, the motor will start automatically when

either pendant button is depressed.

3. Open the air supply valve (callout #4). Using the regulator

knob, adjust the air pressure to a minimum of 80 psi [5,5 bar].

IMPORTANT:

Perform the following step with no load on jack.

4.

Check for proper operation by fully extending and retracting

the cylinder (callout #13). Use the lever on the manual control

valve (callout #5 - PRAMA Series models) or the buttons on

the pendant (callout #6 - PRASA Series models) to control

cylinder movement. To remove air from system, cycle the

cylinder as needed until operation is smooth.

4.4 Using the Handle Assembly to Position the Jack

1.

Push handle lock lever (callout #1) to release lock pin.

2.

With lock pin released, position handle assembly (callout #2)

to desired location and release handle lock lever (callout #1)

to engage lock pin.

3.

The jack can now be tilted back onto the wheels and pushed

or pulled to the work area. Use caution when walking

backwards.

4. If needed, the jack can be lifted using the lifting bar (callout

#3 - if equipped) or the lifting eyebolt(s) (callout #17 - if

equipped).

Note:

Lifting bars are installed on short stroke PRAMA060, PRA_

A100 and PRASA150 Series models. Lifting bars are not used on

any long stroke models or on short stroke model PRASA20016L.

All long stroke models are equipped with

one

lifting eyebolt.

The short stroke model PRASA20016L is equipped with

two

lifting eyebolts. Lifting eyebolts are not present on short stroke

PRAMA060, PRA_A100 and PRASA150 Series models.

3

19

1

5

9

16

7

13

14

4

10

11

12

15

3

8

6

18

2

19

20

17

Figure 2, Major Features and Components - PRASA Series Models

Key:

1. Handle Lock Lever

2. Handle Assembly

3. Lifting Bar

*

4. Air Supply Valve

5. Control Valve, Air Operated

6. Pendant

7. Air Line Lubricator

8. Reservoir Air Breather

9. Air Line Filter/Regulator

10. Air Inlet Connection (1/2" NPT)

11. Oil Fill Plug

12. Oil Filter

13. Hydraulic Cylinder

14. Hydraulic Reservoir

15. Oil Drain Plug

16. Air Muffl

er

17. Lifting Eyebolt

*

18. Wheel Bearing Grease Fitting

19. Tire Air Valve

20. U-Ring Storage

*

Not present on all models.