9

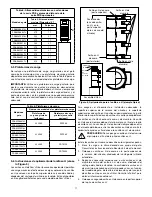

7.0 TROUBLESHOOTING

The information in the Troubleshooting Guide (refer to Table 9) is

intended as an aid to help diagnose and correct various possible

problems that may occur.

For repair service, contact your local Enerpac Authorized Service

Center. Only an Enerpac Authorized Service Center should

service the jack and its components.

CAUTION:

Never tighten or loosen hydraulic fi ttings

while jack hydraulic system is pressurized.

Table 9 - Troubleshooting Guide

Symptom

Possible Cause

Solution

1. Sporadic cylinder

action.

Air trapped in hydraulic system.

Cycle cylinder up and down several times to bleed trapped air.

Low oil level in hydraulic reservoir.

Add Enerpac HF oil as required.

Seal wear and/or other internal damage.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

2. Noisy operation.

Air trapped in hydraulic system.

Cycle cylinder up and down several times to bleed trapped air.

Low oil level in hydraulic reservoir.

Add Enerpac HF oil as required.

Air leaks in hydraulic system.

Check all points where air might leak into system.

Clogged or blocked pump intake

screen.

Have hydraulic reservoir and intake screen fl ushed and cleaned by

Enerpac Authorized Service Center.

3. Oil is overheating.

Low oil level in hydraulic reservoir.

Add Enerpac HF oil as required.

Oil viscosity too high or too low.

Drain and refi ll reservoir with Enerpac HF oil.

High pressure leakage at the pump.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

4. Pump runs but will not

pump oil.

OR

Cylinder moves but

will not lift load.

Seal wear and/or other internal damage.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Control valve needs repair.

Have control valve inspected by Enerpac Authorized Service Center.

Repair or replace as required.

5. Cylinder extends but

will not retract.

Insuffi

cient compressed air volume.

Check air regulator setting. Increase volume of compressed air or increase

size of supply air line to meet airfl ow and pressure requirements.

Internal pressure leaks, or leaking retract

hoses.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Internal relief valve setting or retract side

relief valve setting too low.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Defective over-center valve, secondary

lock valve or control valve.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Pump not developing enough pressure.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

6. Pump does not run.

Insuffi

cient compressed air volume.

Check air regulator setting. Increase volume of compressed air or increase

size of supply air line to meet airfl ow and pressure requirements.

Moisture in compressed air.

Be sure that compressed air is clean, dry and free of water.

Air muffl

er frozen or clogged with ice.

Clean the air muffl

er. Be sure compressed air is clean, dry and free of

water. Check lubricant level in air line lubricator. Use only SAE 10 [ISO 32]

detergent oil or an approved antifreeze lubricant.

Air motor frozen or clogged with ice.

Be sure compressed air is clean, dry and free of water. Check lubricant level

in air line lubricator. Use only SAE 10 [ISO 32] detergent oil or an approved

antifreeze lubricant.

Air motor corroded, damaged, worn or

seized.

Have air motor inspected by Enerpac Authorized Service Center. Repair or

replace as required.

Pump element damaged, worn or

seized.

Have pump element inspected by Enerpac Authorized Service Center.

Repair or replace as required.

7. Jack is diffi

cult to

roll on wheels.

Low tire infl ation pressure.

Check tire infl ation pressure. Add air if low.

Pressure should be 90 psi [6,2 bar].

Wheel bearings need lubrication.

Apply grease to wheel bearings. See Section 6.6.

Wheel locknut out of adjustment.

Loosen locknut until wheel rotates freely.