8

© 2015 Enerpac, All Rights Reserved

PTW Series Pneumatic Torque Wrench

NOTE:

For counterclockwise rotation, the adjustment

lever is set to the “R” position.

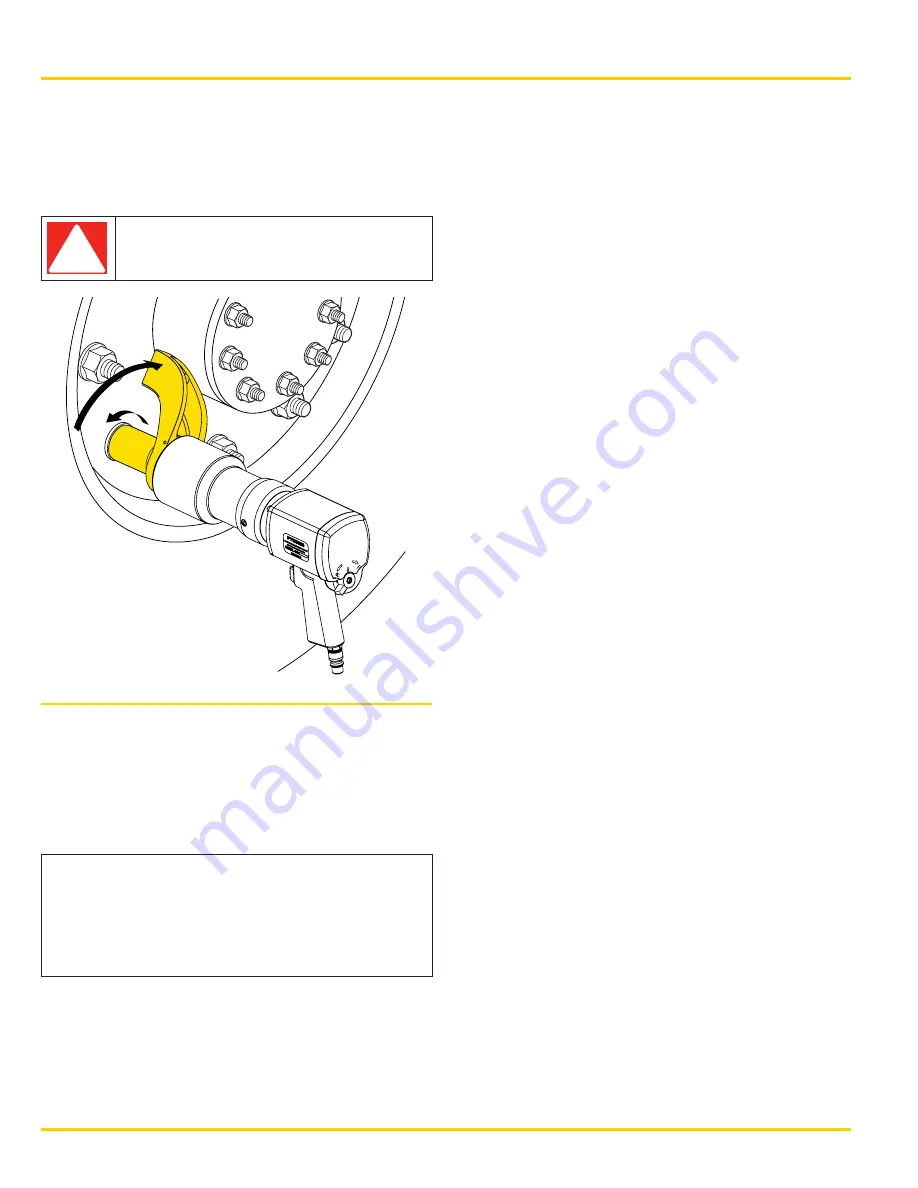

10. Fig. 9 shows the position for the reaction arm

when the square drive rotates counterclockwise.

!

DANGER: Do not place any part of the

body between the reaction arm and

the reaction point.

Fig. 9

11. To tighten a fastener (or to apply torque in the

clockwise direction): Be sure the adjustment lever

is set to the “F” position, and that the reaction

arm is positioned as shown in Fig. 8. Then, fully

depress the trigger, and keep it depressed until

the wrench stalls.

NOTICE:

If the trigger is released before the

wrench stalls, the desired torque will not be applied

to the fastener. Do not repeatedly depress and

release the trigger while tightening a fastener,

as this could result in the incorrect torque being

applied.

12. To loosen a fastener (or to apply torque in the

counterclockwise direction): Be sure that the

adjustment lever is set to the “R” position and

that the reaction arm is positioned as shown in

Fig. 9. Then, fully depress the trigger and keep it

depressed until the fastener loosens.

13. After tightening or loosening is completed,

release the trigger and remove the tool from the

fastener. In some cases, it may be necessary to

briefly operate the tool in the opposite direction

to release the counter torque load from the

reaction arm.

14. When finished using the tool, turn off the air

supply, disconnect the hoses, remove the

reaction arm and store the tool in the case.