© 2015 Enerpac, All Rights Reserved

5

PTW Series Pneumatic Torque Wrench

3 ASSEMBLY AND ADJUSTMENT

The air source must be capable of at least 50 CFM

(85 CMH) at 100 psi (6.9 bar). A minimum hose size

of 1/2 inch (13 mm) must be used. The tool must be

calibrated with the Filter/Regulator/Lubricator (FRL)

that is being used. The PTW equipment (including

tool and FRL) is to be used with an air supply that

is regulated and/or limited to 120 psi (8.3 bar)

maximum.

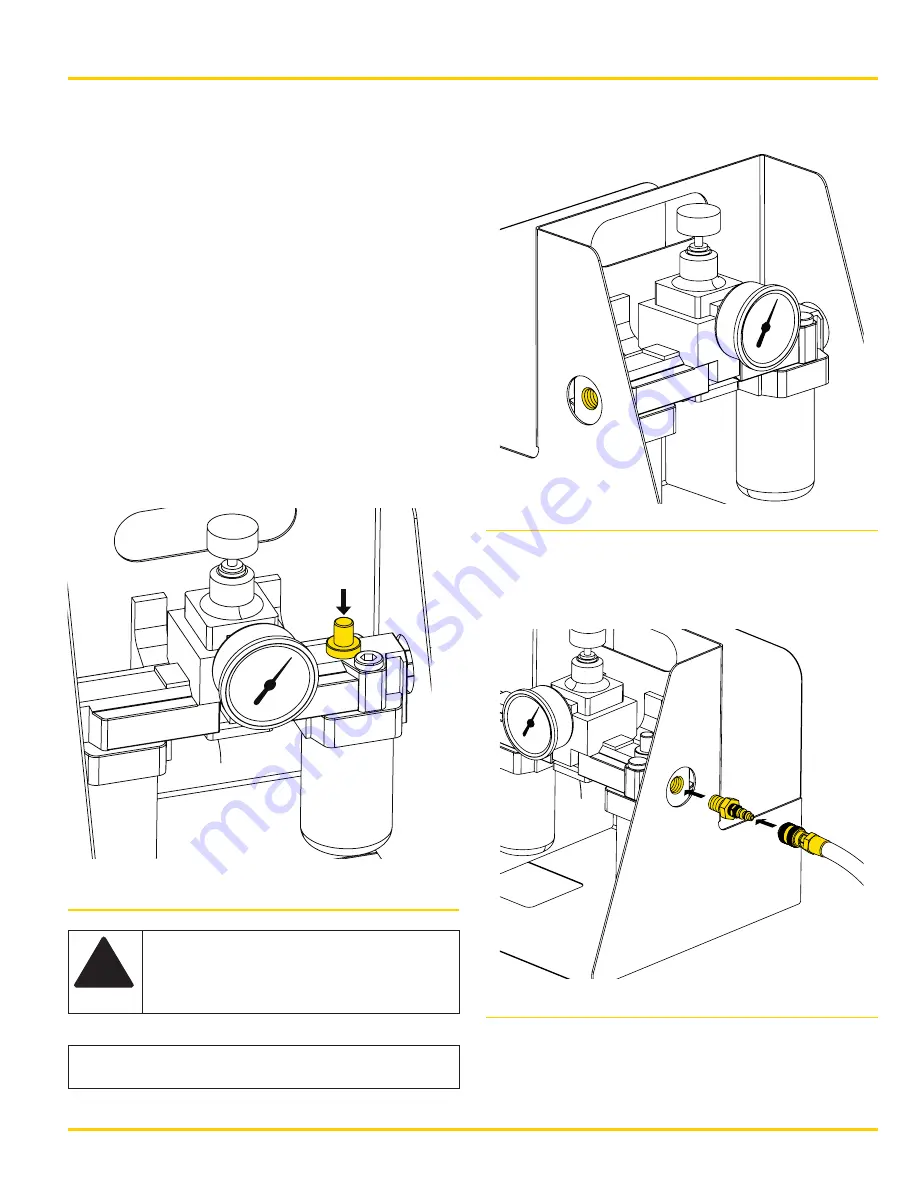

1. Check the air lubricator oil level and fill if needed.

Only use SAE 10 or lighter clean, nondetergent

oil. Remove the cap and add oil if needed.

2. Turn the drip rate adjustment knob to adjust the

drip rate. The drip rate can be viewed through the

clear adjustment knob. The drip rate should be

checked while the tool is operating. Set the drip

rate to between 4 and 6 drops per minute.

Fig. 1

!

WARNING: To prevent hazards created

by hose whip, securely connect all

connections before turning on the air

supply.

NOTICE:

Make sure hoses are free of debris and

the ends are clean before connecting.

3. Install a quick coupler or air hose (not supplied)

into the 1/2 inch NPT inlet port.

Fig. 2

4. Install the supplied male quick coupler into the

outlet port.

5. Connect the air hose to the male quick coupler.

Fig. 3