© 2015 Enerpac, All Rights Reserved

7

PTW Series Pneumatic Torque Wrench

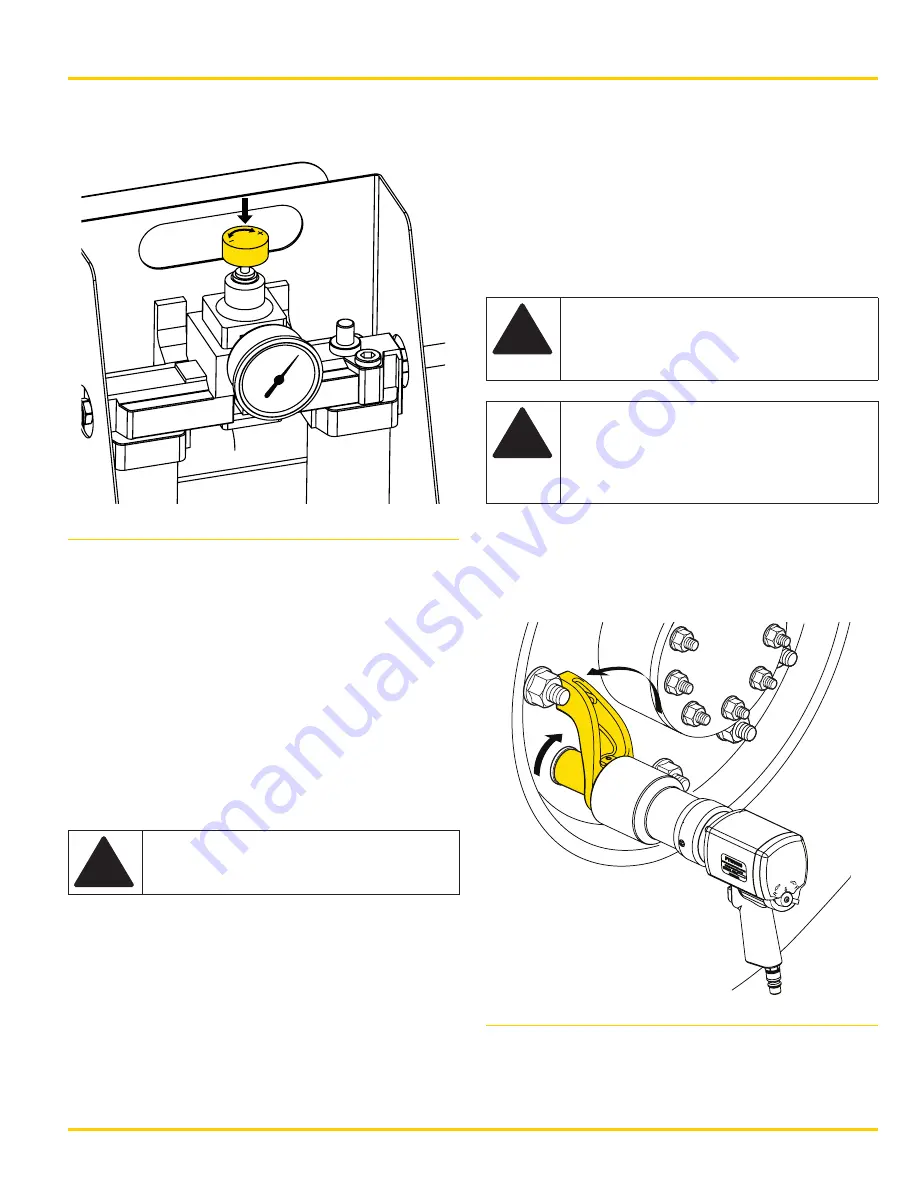

2. The torque output of the tool is set by adjusting

the air pressure using the regulator on the FRL.

Fig. 7

3. Determine the correct air pressure for the desired

torque setting by using the chart from the most

recent calibration. A factory calibration chart is

provided by Enerpac in the tool case.

4. Adjust the lever on the back of the tool indicated

in Fig. 6 so the tool is set to the highest speed

and direction of rotation.

The tool calibration chart provided by Enerpac for

this tool was produced with the tool on the highest

speed. Tool performance in this speed will most

closely reproduce the pressure/torque ratio listed in

this chart.

!

WARNING: Do not attempt to operate

the tool at pressures exceeding the

torque ratings from the supplied chart.

NOTE:

For an accurate torque value, the air pressure

must be adjusted with the tool free-running (rotating

freely, not under load).

5. Fully depress the trigger of the tool and adjust

the regulator to the correct pressure while the

tool is free-running.

6. Make sure the appropriate reaction arm is

installed onto the tool.

7. Determine the correct size socket and install it

on the square drive. It is recommended that the

socket be pinned onto the square drive.

8. Install the socket onto the fastener and rotate the

body so the reaction arm is positioned against

the reaction point.

!

WARNING: To prevent serious

crushing injury, always keep all body

parts away from the reaction point

when the tool is in use.

!

CAUTION: When in operation, the

reaction arm rotates in the opposite

direction of the square drive. Always

make sure the reaction arm is

positioned against a solid fixed object.

NOTE:

For clockwise rotation, the adjustment lever is

set to the “F” position.

9. Fig. 8 shows the position for the reaction arm

when the square drive rotates clockwise.

Fig. 8