L4627_b

13

SHS Model

SHC Model

HPU Model

SHS45520MW/MJ

SHC5520

SHP414MW/MJ

SHC5520P

SHC5520S

SHS45540MW/MJ

SHC5540

SHC5540P

SHC5540S

SHS45560MW/MJ

SHC5560

SHC5560P

SHC5560S

SHS48520MW/MJ

SHC8520

SHP421MW/MJ

SHC8520P

SHC8520S

SHS48540MW/MJ

SHC8540

SHC8540P

SHC8540S

SHS48560MW/MJ

SHC8560

SHC8560P

SHC8560S

SHS411020MW/MJ

SHC11020

SHS421MW/MJ

SHC11020P

SHC11020S

SHS411040MW/MJ

SHC11040

SHC11040P

SHC11040S

SHS411060MW/MJ

SHC11060

SHC11060P

SHC11060S

6. Installation

6.1 Handling

The frame can be lifted with a crane, holding it by the

lifting points previously explained. Refer to paragraph 1

for further information.

6.2 Hydraulic Oil Requirements

Use of Enerpac HF Series ISO 32 hydraulic oil is

recommended. Enerpac HF oil is available at your local

Enerpac Distributor or Authorized Service Center.

NOTICE

• Failure to use the correct oil type (high-quality ISO 32

hydraulic oil) may result in damage to cylinder hydraulic

components and will void the product warranty.

• Be sure that the oil is clean. The oil cleanliness should

be maintained to a maximum level of 18/16/13 per the

ISO4406 standard. If the oil develops a milky, cloudy

or dark appearance, it should be changed immediately.

• To avoid overfilling and possible equipment damage,

add oil to the pump reservoir only after all Synchoists are

completely retracted and system pressure is released.

• When using a hand-operated pump to power the

cylinder(s), it is permissible to use a high-quality brand

of ISO 15 hydraulic oil. The lower oil viscosity will result

in reduced pumping effort, especially in cold weather

conditions.

6.3 Hydraulic Connections

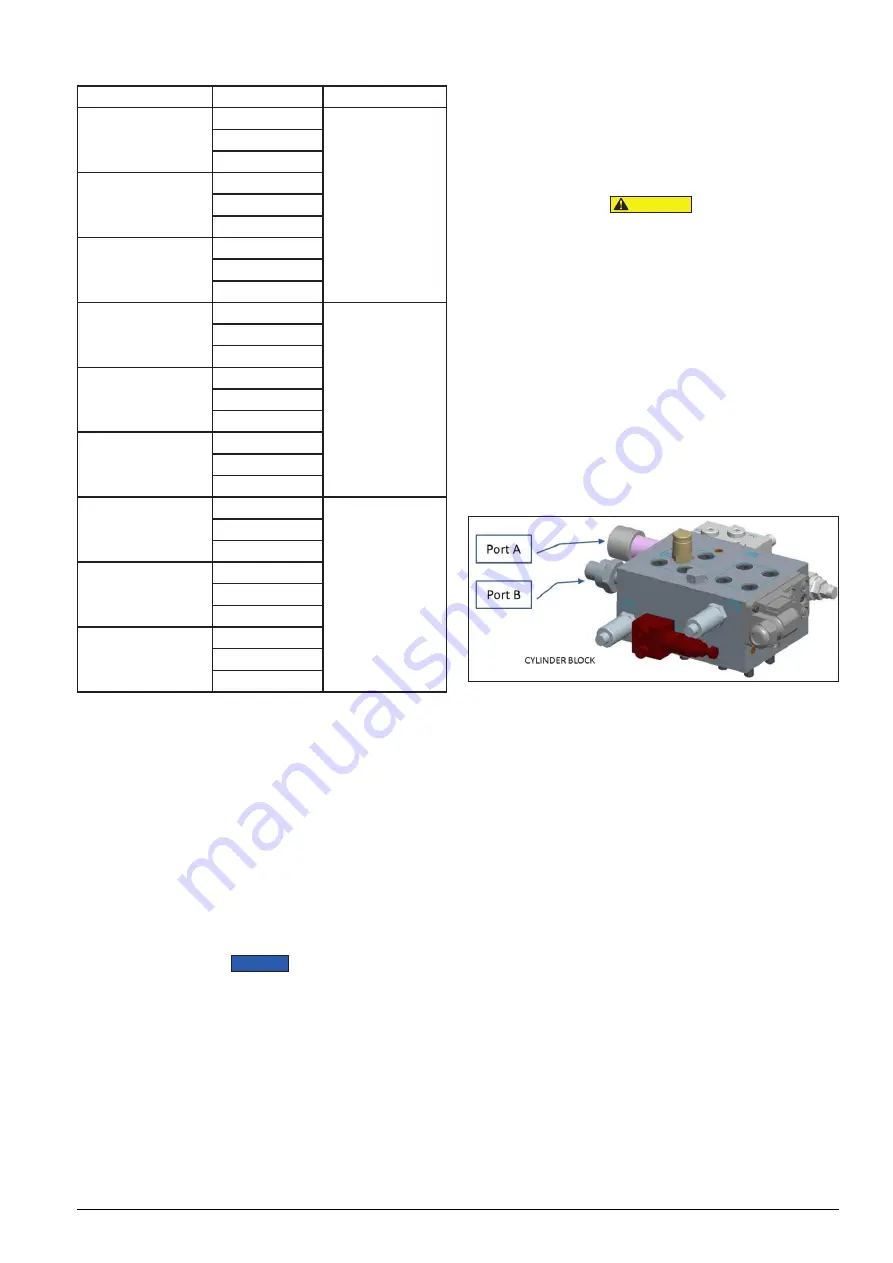

CAUTION

On double-acting cylinders be certain that hoses

are connected to BOTH couplers. Never attempt to

pressurize a double-acting cylinder if only one hose

is connected.

For installation of Synchoist cylinders, it is not necessary

to start-up the power pack.

It is advisable to connect the hoses with retracted and

horizontal positioned cylinders. If hoses are connected

with cylinders in the vertical position it may be impossible

to connect the hose in the small chamber due to the

pressure created by plunger weight.

Connect hydraulic hoses as follows:

• A Port is connected to the retract outlet of the HPU.

• B Port is connected to the advance outlet of the

HPU.

Figure 9: Distribution manifold ports

Perform the following steps to correctly connect the

hoses:

1. Keep cylinders connected to a hydraulic system

with a fluid cleanliness level minimum of NAS 1638

Class 6.

2. Remove dust covers/rubber plugs from oil ports

3. Inspect all threads and fittings in search of wear or

damage signs and replace as needed.

4. Clean all threads and fittings.

5. Make hydraulic connections for double-acting

cylinders using two hoses.

6. Fully hand-tighten all couplers. Loose coupler

connections will block the flow of oil between the

pump and the cylinder.

Check for leaks in system and have repaired by qualified

personnel.