9

9. Lubricate the o-rings and backup washers. Insert the shear

seal assemblies into body (item 23) by hand.

10. Tighten body onto cap with 2 screws (item 24) with a 5/32"

hex wrench, hand tight.

11. Place 4 o-rings (item 25) onto body.

12. Mount upper valve assy onto manifold or locking valve block

using 4 socket head cap screws (item 7, fi gure 1A & 1B).

Torque to 28-34 ft-lbs [38-46 Nm].

13. Insert spring (item 6, fi gure 1D) into hole in valve cap (item 9).

Install ball (item 5) onto the spring.

14. All models except VM33M & VM43M: Place disk (item 4) with

sharp edged side facing upwards onto the shaft and resting

on ball. Place handle (item 3) onto shaft.

15. Models VM33M & VM43M Only: Place handle cap (item

66), lever (item 67) and knob (item 68) onto shaft as an

assembly.

16. Insert washer (item 2) onto shaft. Apply Loctite 222 to threads

on screw (item 1) and hand tighten.

Procedure for Locking Valve Blocks only

1. Seat a new ball (item 35, fi gures 2 & 3) onto seat (item 39)

with press (195 psi with 10-ton ram or 380 psi with 5-ton

ram). Make two assemblies for a 4-way block or only one for

a 3-way block. Set these parts aside.

2. Place o-ring (item 36) and washer (item 37) onto each seat

(item 39) and lubricate with grease. Set these parts aside.

3. Place gasket (item 32) and o-ring (item 33) onto each plug

(item 31). Set these parts aside.

4. Lubricate bore in valve block (item 43) with oil.

5. On 3-way blocks only: Place the uncoined seat assembly

(items 36, 37 & 39 - without ball) into one end of bore. Use

special tool AT100479. Do not install ball (item 35) or spring

(item 34) on this end. Refer to fi gure 2.

6. On 4-way blocks only: Place the fi rst seat assembly (items

36, 37 & 39) into either end of bore with ball (item 35) facing

up. Use special tool AT100479. Refer to fi gure 3.

7. On 4-way blocks only: Dip a spring (item 34, fi gure 4) in

grease and place into plug (item 31).

8.

Thread plug assembly (items 31-33 and item 34, if used) into

bore opening on same end as seat was installed. Torque to

85-95 ft-lbs [115-129 Nm].

9.

Turn over valve block (item 43, fi gures 2 & 3) so that opposite

end of bore is facing up. Lubricate bore with oil.

10. Assemble piston (item 42) with o-ring (item 41) and 2 backup

washers (item 40). Place piston assembly (items 40-42) into

bore. Use special tool AT100479-1.

11. Place the second seat assembly (items 36, 37 & 39) into bore

with ball (item 35) facing up. Use special tool AT100479.

12. Dip spring (item 34) in grease and place into plug (item 31).

13. Thread plug assembly (items 31-33) with spring (item 34)

into bore opening. Torque to 85-95 ft-lbs [115-129 Nm].

14. Place o-rings (item 26, fi gure 1B) onto manifold (item 27).

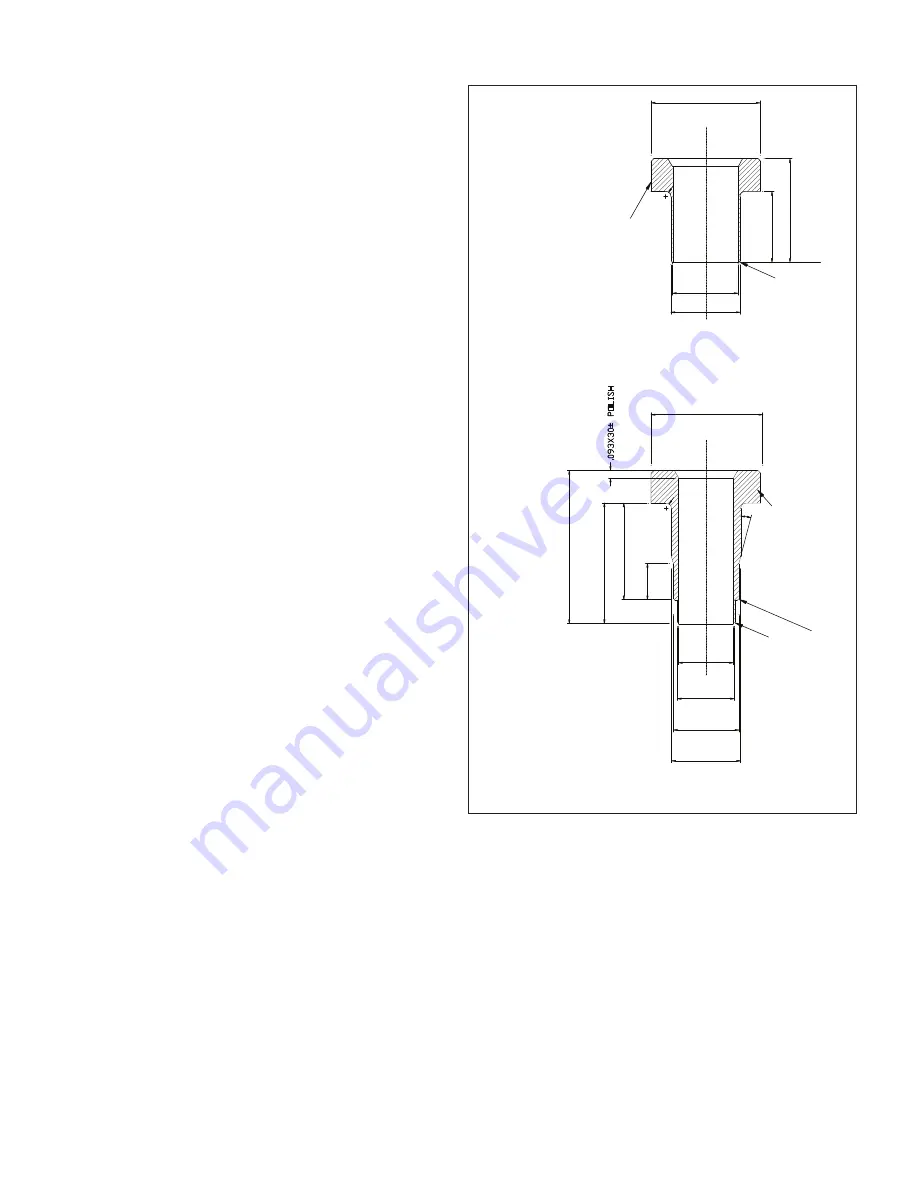

Special Tools

Ø1.25

Ø1.25

Med. Knurl

Med. Knurl

R.120

R.120

Ø.752/.753 Polish

Ø.795/.793 Polish

1/64X45 Chamf

1/64X45 Chamf.

Ø.628/.630 Polish

Ø.655/.654 Polish

Ø.746/.747 Polish

Ø.795/.793 Polish

.790/.795

1.187

15°

.406

1.75

1.102/1.105

1.370/1.365

Figure 9, Special Tools

Relief Valve Adjustment

The valve assembly is equipped with a user-adjustable relief

valve. Adjust pressure as follows:

VM33, VM33M, VM43 and VM43M Only

1.

Install a 0-15,000 psi [0-1,035 bar] gauge in the “A” port (see

Figure 10).

2. VM43 and VM43M Only: Place a 3/8" pipe plug in the “B”

port and torque to 25 ft-lbs [33 Nm].

3. Loosen the relief valve locknut to permit adjustment of set

screw.

AT100479

Use for installing seats,

item 39, into the bore.

(see fi gures 2 & 3)

AT100479-1

Use for installing piston

assembly, items 40-42,

into the bore.

(see fi gures 2 & 3)

Summary of Contents for VM33

Page 55: ...55 ...