Enersol Pool Panel Installation Guide

11 |

P a g e

6 - SYSTEM REGULATION

OPTIONS (continued)

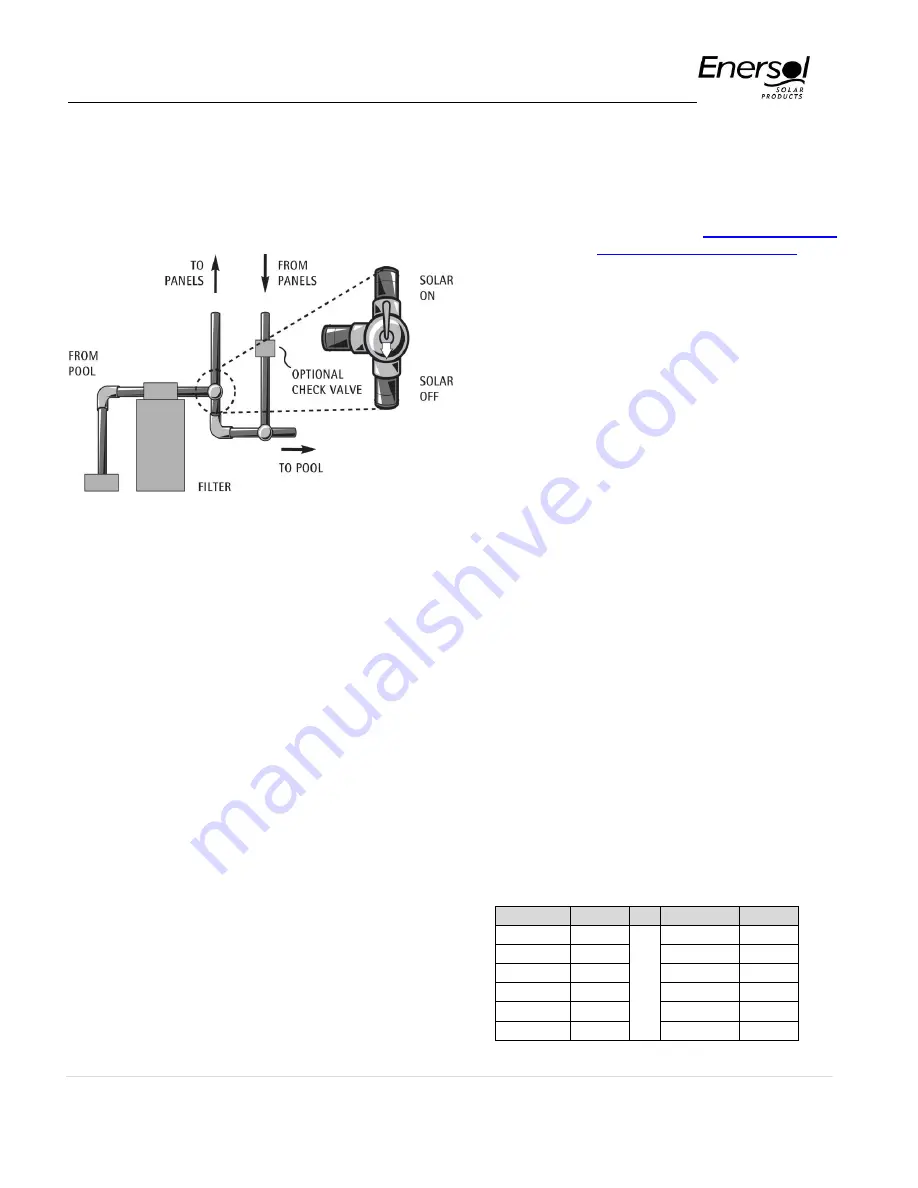

3-WAY MANUAL VALVE

b)

A

CHECK

VALVE

is

optional,

but

suggested, to be installed on the return line.

This will prevent back flow to the panels, and

is also required for the

Summerization

of

the system. In some cases a check valve

can prevent losses from heat thermo

siphoning out of the pool.

c)

An

AUTOMATIC VALVE

relies on water and

panel temperature sensors to divert the

water. EnerWorks suggests the Aqua Solar

controller kit. The kit comes with a 3-port

diverter valve, actuator, control box and two

sensors. Follow manufacturer’s instructions

for installation of automatic control box,

motorized valve (actuator) and controls.

• Install the Control Box as outlined in

manufacturer’s instructions. Be sure to wire

correctly.

• The 3-port valve (diverter) is installed as above.

• Remove the locking knob and handle.

• Remove 4 screws from the valve (fit actuator on

valve to determine which screws to remove).

• Align the actuator; rotate the actuator until holes

on the actuator align with the screw holes.

• Use the 4 supplied screws to secure in place.

• Plug the actuator in the Control Box in the

FWD

VALVE

socket.

• Flick the switch to

SOLAR TEST

. Synchronize the

valve handle by flipping the toggle switch at the

bottom of the actuator between

ON 1

and

ON 2

to

rotate the handle so it points to the solar panel

feed line. See full instructions for valve actuator in

package, or visit our web site,

www.enersol.com

and look under “

System Automatic Controller

”.

d) WATER SENSOR

Install the plastic cylinder shaped sensor by

drilling a 5/16” hole into the pipe usually

between the filter and diverter valve. The

gear clamp holds the sensor in place. Two

wired connectors are supplied to connect the

sensor to two line sensor wire. The other end

is wired into the control box (pool sensor

screws).

e) PANEL SENSOR

Install the sensor on the roof or rack where it

receives sunlight similar to the solar panels.

Two wire connectors are supplied to connect

the sensor to two wire sensor cable. The

other end is wired into the Control Box (solar

sensor screws). The plastic wire protector fits

in the hole located in the bottom of the control

box.

f) VACUUM BREAKER

A vacuum breaker is not necessary, as the

Enersol Panels do not collapse when drained.

g) OHM-METER

Use an Ohm meter to check the resistance in

the sensors. The Ohms readings should

correspond with the sensor temperature. Use

the chart below to determine if the sensor is

sensing proper temperatures.

Temp °F

Kohms

Temp °F

Kohms

65

13.5

95

6.5

70

11.9

100

5.8

75

10.5

105

5.2

80

9.3

110

4.7

85

8.2

115

4.2

90

7.3

120

3.8